Silicone cable is not merely a wire; it is a critical survival mechanism for electronics operating in hostile environments. While standard electrical wire serves well in static, room-temperature devices, it becomes a liability when exposed to extreme thermal cycling, high-frequency vibration, or corrosive chemicals. Engineers and hobbyists often discover this the hard way when standard PVC or XLPE insulation cracks in freezing temperatures, melts during soldering rework, or outgasses in sensitive optical setups. To ensure reliability, one must look beyond basic conductivity and evaluate the mechanical and chemical architecture of the cabling itself.

The distinction between a successful deployment and a catastrophic failure often lies in the insulation’s ability to withstand stress without compromising electrical isolation. This article explores the chemical architecture that gives silicone its unique properties, the decision-making criteria for high-performance builds, and the Return on Investment (ROI) logic for switching to silicone-insulated cabling. We will examine why industries ranging from medical technology to aerospace rely on this material to solve complex connectivity challenges.

Key Takeaways

Temperature Range: Operates reliably from -60°C to +200°C (up to 300°C with specific formulations), outperforming PVC significantly.

Flexibility Mechanism: High strand counts combined with soft-touch silicone allow for tight bend radii in robotics and drones without work-hardening or fatigue.

The "Ash" Safety Factor: Unlike plastic, silicone burns into a non-conductive silica ash, maintaining circuit integrity during fire events.

Primary Trade-off: While chemically inert and thermally stable, silicone lacks the mechanical abrasion resistance of Teflon or Nylon and may require additional sleeving.

The Anatomy of Silicone Cable: How It Works

To understand why silicone cable performs differently than standard wire, we must look at its molecular foundation. Most standard cables, such as PVC (Polyvinyl Chloride) or Polyethylene, rely on a carbon-based backbone. While effective for general use, carbon chains are susceptible to breaking down under heat and UV exposure. Silicone rubber, however, is built on a siloxane backbone—an alternating chain of silicon and oxygen atoms.

Chemical Backbone (The "Why")

The primary reason for silicone's endurance is the strength of the Silicon-Oxygen (Si-O) bond. Chemically, the bond energy required to break silicon-oxygen links is significantly higher than that of carbon-carbon links found in plastics. This superior bond strength translates directly into thermal resistance. The material does not easily denature or lose structural integrity when subjected to energy spikes in the form of heat or radiation. It remains stable, ensuring the insulation does not become brittle or melt into a conductive mess.

Conductor Architecture

The insulation is only half the story; the conductor inside must also withstand the environments silicone is designed for.

Tinned Copper: You will rarely find bare copper inside high-quality silicone cabling. At the elevated temperatures (up to 200°C) where silicone thrives, bare copper oxidizes rapidly, leading to increased resistance and eventual failure. Manufacturers use tinned copper strands because the tin layer acts as a barrier against oxidation and corrosion, preserving the conductor's efficiency over decades of use.

High Strand Count: Flexibility is a hallmark of silicone wire. This is achieved not just by the soft rubber jacket but by the conductor design. A standard 12 AWG house wire might have a solid core or 7 thick strands, making it stiff. A 12 AWG silicone cable, however, might contain hundreds or even thousands of ultra-thin strands (often 0.08mm in diameter). This high strand count allows the cable to behave like a fluid rope rather than a rigid bar, essential for dynamic routing in gimbals and robotics.

The "Memory" Effect

A frequently overlooked property of silicone is its resistance to "compression set." In many thermoplastics, if you clamp a cable tightly, the material eventually flows away from the pressure point (creep), causing the connection to loosen over time. Silicone exhibits a "memory" effect; it resists this deformation and pushes back against the clamp or seal. This ensures that waterproof seals and mechanical connections remain tight despite years of thermal expansion and contraction.

Key Performance Evaluation Dimensions

When selecting cabling for critical projects, engineers evaluate performance across three primary dimensions: thermal endurance, chemical inertness, and safety limits. Silicone offers a unique profile in each of these categories compared to traditional polymers.

Thermal Endurance & The "Soldering" Test

The operational range of silicone is its most famous attribute. On the high end, standard silicone cables are rated for continuous operation at 200°C, with intermittent tolerance up to 300°C depending on the specific formulation. This is vastly superior to PVC, which typically softens around 70°C and melts at 105°C.

On the low end, silicone remains flexible down to -60°C. In the aerospace industry, where components are exposed to high-altitude freezing, standard cables can become as brittle as glass, shattering under vibration. Silicone retains its elastomeric properties, absorbing movement without cracking.

For prototypes and assembly technicians, the "soldering test" is the most immediate benefit. When soldering a connector to a PVC wire, the heat travels up the conductor, causing the insulation to shrink back or melt, leaving exposed wire. Silicone insulation is thermoset; it does not melt or retreat under the heat of a soldering iron. This significantly reduces rework time and ensures a clean, professional finish.

Chemical & Environmental Inertness

Silicone is naturally hydrophobic and chemically inert, but its interaction with other materials is nuanced. One distinct advantage is potting adhesion. Unlike Teflon (PTFE), which is notoriously difficult to bond to, silicone adheres well to many potting compounds and encapsulants. This makes it the ideal choice for creating fully sealed, waterproof electronic units.

Furthermore, silicone possesses natural resistance to UV radiation and ozone without requiring special additives. While PVC jackets placed outdoors will eventually chalk, fade, and crack due to UV exposure, silicone maintains its integrity, extending the lifespan of outdoor sensor arrays and solar equipment.

Safety & Circuit Integrity (The Fused Silica Mechanism)

Perhaps the most critical safety feature is how silicone behaves during combustion. When typical plastic insulation burns, it melts into a conductive liquid blob or produces conductive carbon char, both of which can cause short circuits that propagate the fire.

Silicone burns differently. When the organic components combust, the remaining silicone structure converts into a fused silica ash. This ash is white, sand-like, and most importantly, non-conductive. It forms a ceramic-like layer around the conductor that continues to insulate the wire even after the fire has consumed the rubber. This "circuit integrity" is vital for emergency lighting, fire alarms, and critical systems that must function long enough to allow for safe shutdown or evacuation.

| Feature | Standard PVC Cable | Silicone Cable |

| Temperature Range | -20°C to +80°C | -60°C to +200°C |

| flexibility | Stiff, prone to fatigue | Ultra-flexible, high fatigue life |

| Combustion Result | Toxic smoke, conductive char | Non-conductive silica ash |

| Soldering Heat | Melts and shrinks back | Unaffected |

Validating Applications: From Drones to Medical Devices

The specific properties of silicone allow it to serve disparate industries. By analyzing Silicone Cable applications, we can see how different sectors leverage these wires to solve specific failure modes.

Aerospace Industry & Drones

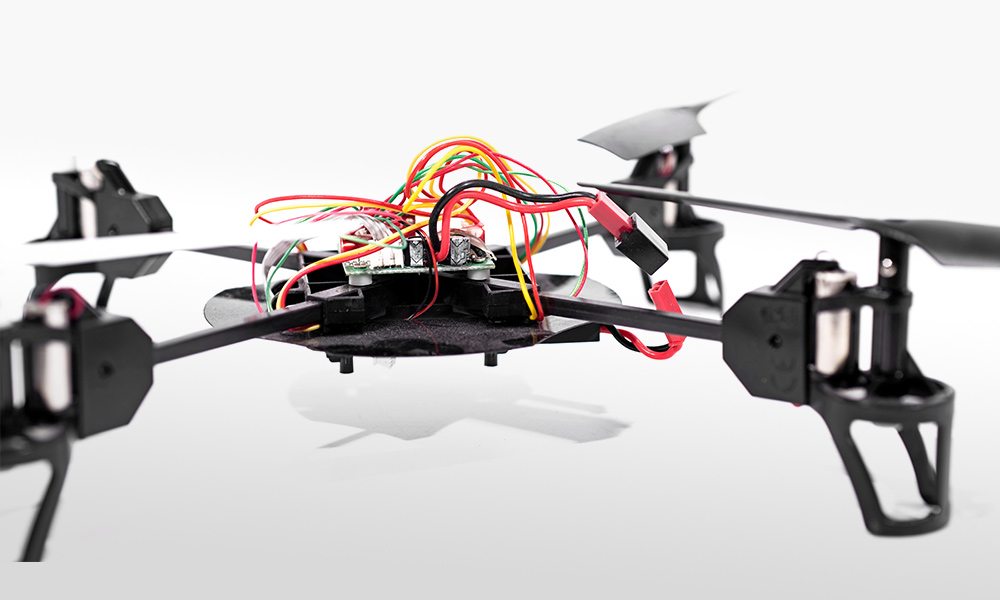

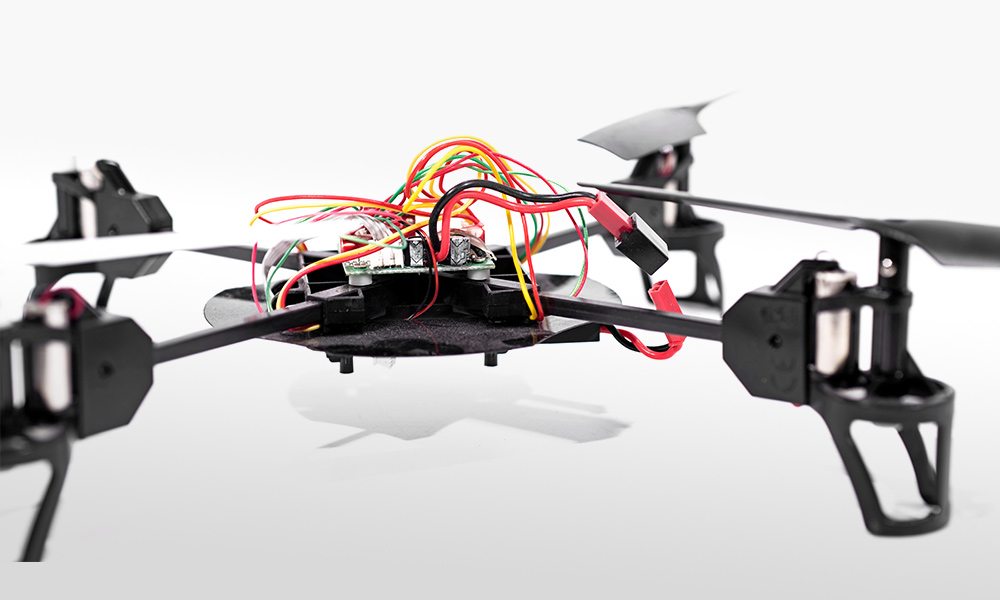

In the world of UAVs (Unmanned Aerial Vehicles) and aviation, every gram counts. Silicone Cable and Drones are a perfect pairing due to the material's high current-carrying capacity. Silicone can handle higher temperatures before degrading, allowing engineers to run higher currents through thinner gauge wires, effectively saving weight.

Moreover, flight involves constant vibration. Rigid insulation transfers this vibration energy directly to the copper conductor, leading to work-hardening and micro-fractures. The soft silicone jacket acts as a damper, absorbing vibration energy and reducing mechanical stress on the copper. Combined with resistance to "cold soak" at high altitudes, it ensures that power delivery systems do not fail during critical flight maneuvers.

Medical & Sterilization

Medical environments demand rigorous hygiene standards. Tools and devices must undergo sterilization, often involving autoclaves that use high-pressure steam at 134°C. Most plastics degrade rapidly under these conditions, losing flexibility or cracking. Silicone is one of the few materials capable of withstanding repeated autoclave cycles without significant degradation.

Additionally, biocompatibility is non-negotiable. Silicone is generally hypoallergenic and inert. High-quality silicone cables comply with ISO 10993 standards for skin contact, making them safe for patient-monitoring leads and handheld surgical instruments where the cable may inadvertently touch the patient or the operator.

Industrial Automation

In automated factories, cables are often routed through drag chains or robotic arms that repeat the same motion millions of times. Standard PVC cables will eventually work-harden and crack due to this repetitive stress. Silicone's high-flex life ensures that power and data transmission remain uninterrupted, significantly reducing downtime and maintenance costs in 24/7 production environments.

The Honest Trade-Offs: When NOT to Use Silicone

Despite its impressive capabilities, silicone is not a magic solution for every application. It has distinct physical limitations that engineers must respect to avoid costly errors.

Mechanical Weakness (Abrasion & Tear)

The "Achilles Heel" of silicone is its mechanical softness. While it has excellent tensile strength, it suffers from poor abrasion and cut-through resistance compared to tougher materials like Teflon (PTFE), Nylon, or even PVC. If a silicone cable is dragged over a sharp metal edge or rough concrete, the insulation can tear easily, exposing the live conductor.

Mitigation Strategy: If the application involves abrasive contact, silicone cables generally require secondary protection. This often takes the form of a Techflex sleeve or a Glass Fiber Braid. For static routing inside a chassis, using grommets at pass-through points is mandatory.

Chemical Permeability

While silicone is chemically inert to many acids and bases, it is permeable to certain gases and organic solvents. It can swell significantly if immersed in specific fuels or oils (like jet fuel or kerosene) for extended periods. It acts like a sponge in these scenarios, losing its mechanical strength. For applications requiring direct immersion in hydrocarbon tanks, a barrier layer or a different material like Fluoropolymer may be required.

Cost Analysis (TCO)

Silicone cable commands a premium price compared to PVC. However, the Total Cost of Ownership (TCO) often favors silicone in demanding applications. The initial Capital Expenditure (CAPEX) is higher, but the Operational Expenditure (OPEX) drops due to fewer cable replacements, less downtime, and faster assembly speeds during soldering. When the cost of a single failure exceeds the cost of the spool of wire, the upgrade is economically justified.

Sourcing Guide: How to Select the Right Silicone Cable

Not all silicone cables are created equal. When sourcing, specific certifications and metrics distinguish industrial-grade options from generic hobbyist wires. If your project involves the aerospace industry or critical medical devices, rigorous selection criteria apply.

Verify the Voltage Rating

It is crucial to distinguish between voltage needs. High-voltage automotive applications (such as EV battery interconnects) require vastly different specifications than low-voltage electronics. For high-voltage setups, look for "Low Corona" variants designed to prevent ionization of the air around the cable, which can degrade insulation over time.

Check the Standards (Compliance)

Reliable cable should carry industry-recognized certifications:

UL 3239 / UL 3135: These are common standards for high-voltage and high-temperature appliance wiring, ensuring the cable has passed rigorous flammability and electrical testing.

Class F/H Motors: If the wire is for motor windings or connections, ensure it meets Class F (155°C) or Class H (180°C) thermal insulation classes.

FDA / USP Class VI: For food processing or medical applications, these certifications confirm that the material is safe for direct contact and does not release harmful extractables.

Strand Count Verification

Finally, inspect the strand count if the application involves movement. A cable might be sold as "silicone," but if it contains fewer, thicker copper strands, it will be stiff and prone to fatigue. Specify "High Flex" or verify the strand diameter (e.g., 0.08mm or 0.05mm) to ensure you are getting the mechanical flexibility required for dynamic applications like robotics or gimbals.

Conclusion

Silicone cable is not a generic replacement for PVC; it is a specialized engineering material designed to manage heat, cold, flexibility, and chemical safety in ways that standard plastics cannot. It excels in environments where failure is not an option—whether that is inside a surgical autoclave, on a drone flying at freezing altitudes, or within a high-heat industrial furnace.

The final verdict for engineers and buyers is clear: use silicone when the cost of failure—be it melting insulation, cracking due to cold, or vibration fatigue—exceeds the marginal cost of the cabling material itself. Evaluate the current failure points in your assembly. If you find evidence of heat damage, stiffness, or difficult soldering rework, upgrading to silicone is a logical and high-ROI decision.

FAQ

Q: Is silicone cable waterproof?

A: Silicone is naturally hydrophobic (repels water) and offers excellent waterproof characteristics for the material itself. However, water can still travel between the wire strands (capillary action) if the ends are not sealed. The major advantage of silicone is its ability to bond effectively with potting compounds, allowing for the creation of truly waterproof, sealed cable assemblies.

Q: Can silicone wire be buried underground?

A: Direct burial is generally not recommended for standard silicone wire due to its low mechanical abrasion resistance and potential for rodent damage. While it resists moisture, the soft insulation can be crushed by rocks or soil pressure. If underground use is necessary, the silicone wire should be run inside a protective conduit or PVC pipe.

Q: Why is the strand count so high in silicone cables?

A: The high strand count (often consisting of hundreds of 0.08mm tinned copper strands) is what provides the cable's signature "rope-like" flexibility. This design minimizes stiffness and prevents metal fatigue (work-hardening) in dynamic applications like robotics or gimbals, where the wire must bend repeatedly without breaking.

Q: Does silicone insulation melt?

A: No, silicone is a thermoset material, meaning it does not melt into a liquid when heated. Instead of melting, extreme heat eventually causes it to combust and turn into a non-conductive silica ash. This behavior preserves circuit integrity during fire events, unlike PVC, which melts and can cause short circuits.