You can find real silicone cable in 2026 by looking at flexibility, surface finish, markings, and certification labels. Take simple steps to find true silicone rubber and stay away from fake ones. Pick cables that feel soft and bend easily. Look for clear markings and labels that show they follow rules. Silicone rubber with good insulation works well outside. Fake silicone cables can cause big problems:

Hardware can break and devices can get damaged

Security risks, like malware attacks, can happen

Bad quality can make important things fail

Use a checklist every time you buy to keep your equipment safe and make sure everything works right.

Key Takeaways

Test how flexible and soft the cable is. Real silicone cables bend without trouble and feel smooth. Fake ones are hard and do not bend well.

Check for clear labels and markings. Real cables show certifications and correct details printed on them.

Look at the surface of the cable. Real silicone cables look shiny and smooth. They do not have cracks or dull areas.

Make sure the cable has the right temperature and voltage ratings. This helps you know if the cable fits your project and keeps things working.

Use a checklist before you buy a cable. This helps you check if the cable is real and keeps your equipment safe.

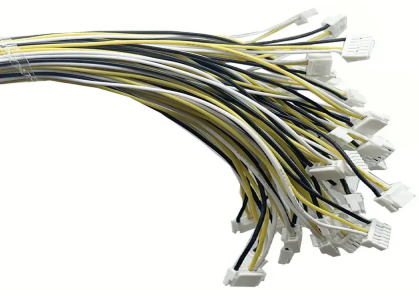

Physical Features of Silicone Cable

Flexibility and Touch

When you hold a silicone cable, it bends very easily. Silicone rubber makes the cable super flexible. This helps when you need to move or twist wires a lot. You can test this by bending the cable gently. It should feel soft and go back to its shape. There should not be any cracks or hard spots. This flexibility is important for outdoor jobs, robots, and things that move often.

Real silicone cables bend without trouble and feel soft.

Fake cables are stiff and can break or lose their shape.

Silicone rubber stays bendy in hot or cold weather.

If you touch silicone and other materials, you will notice a difference. The table below shows how each one feels:

Material | Texture Description |

Silicone | Very soft, smooth, velvet-like; no plastic smell |

TPE | Soft, rubbery, silk-smooth |

PVC | Hard, shiny, plastic feel |

You can use your hands to check for real silicone insulation. Silicone rubber feels smooth and almost like velvet. PVC feels hard and like plastic.

Color and Surface Finish

Silicone cable is usually bright and has solid colors. The outside looks smooth and even. You should not see rough spots or faded areas. Silicone rubber does not fade in sunlight and keeps its color for a long time. If you see a cable with uneven color or a dull look, it might not be real silicone.

Look for a shiny, smooth surface.

Check if the color is bright and the same everywhere.

Silicone rubber does not crack or peel, even after a long time.

You can use these clues to pick the right cable. Silicone insulation keeps the wire safe and looking new.

Markings and Labels

Markings and labels help you know if a silicone cable is real. Good cables have clear writing along the side. You should look for these things:

Cable size (like 14 AWG or 10-3 w/G)

UL file marking (for example, E802357)

Type of cable label (like THHN or RHHW)

Maximum voltage (like 600v or 12.5kV)

Type of conductor label (cu for copper, al for aluminum)

Specification label (UL, TUV, ISO)

Temperature rating (like 75°C or 90°C)

Other labels (SUNLIGHT RESISTANT, OIL RESISTANT I)

New silicone cables use special security features to stop fakes. You can check for:

Holographic Fingerprint™: Scan with your phone to check if it is real.

Holographic labels: Look for fancy patterns and colors.

Security inks: These change color with special light or heat.

Microtext labels: Tiny words you need a magnifying glass to see.

Tip: Always look at the markings and labels before you buy. If the print is faded, missing, or looks copied, the cable might not be real silicone rubber.

You can use these physical signs to make sure you get real silicone cable every time.

Technical Specs for Silicone Insulated Wire

Temperature and Voltage Ratings

Check the temperature and voltage ratings before you buy. These ratings tell you how much heat and electricity the wire can handle. Silicone rubber lets wires work in very hot places. Many wires can handle up to 200°C. Some wires can go up to 250°C for short times. Voltage ratings can be from 600 volts to 100,000 volts. The type of wire decides the rating.

Here is a table that shows common ratings for silicone insulated wire:

Cable Type | Voltage Rating | Temperature Range |

Tuffsil | 600 VDC to 100 KVDC | 55 to 200 °C (250 °C intermittent) |

UL 3239 | 5 KVDC to 60 KVDC | N/A |

UL 3616 | 20 KVDC to 60 KVDC | N/A |

Sil-KOAT | 1 KVDC to 30 KVDC | -55 to 200 °C |

SIA, SIA-F, SIAF-GL, SIHF | 300/500V or 600/1000V | -60 °C to +180 °C |

If a wire has low ratings, it may not be real silicone. Always match the wire’s specs to your job.

Certification Marks (UL, CSA, HAR, VDE)

Look for certification marks on every silicone insulated wire. These marks show the wire passed safety tests. Common marks are UL, CSA, HAR, and VDE. Each mark means the wire meets strict safety rules. You can find these marks printed on the wire or in the product details.

Tip: If a wire does not have any certification marks, ask the seller for proof. Certified silicone wires protect your equipment and keep you safe.

Here is a table to help you check for proper documentation:

Requirement | Description |

CE Marking | Must follow CE marking under EU rules (LVD, EMC, RoHS). |

International Standards | Should meet IEC 60245, UL 3122, or UL 3367 for voltage and temperature. |

Supplier Documentation | Ask for test reports and certificates from the supplier. |

Compliance with 2026 Standards

Make sure your silicone insulated wire follows the latest rules. In 2026, standards like UL, IEC, and RoHS set new safety requirements. These rules help keep wires safe for people and the environment. Silicone rubber wires now need to meet stricter limits for harmful substances. Always check if the wire meets these standards before you buy.

Real silicone insulated wire is better than fake cables. Genuine silicone wires have high thermal stability and strong electrical properties. They resist fire and corrosion. Fake wires often fail these tests and can cause problems.

Specification | Genuine Silicone Insulated Wire | Non-Silicone/Counterfeit Cables |

Thermal Stability | High | Low |

Electrical Properties | Excellent | Poor |

Flame Retardancy | High | Low (softens at 105 degrees) |

Corrosion Resistance | Excellent | Poor |

Environmental Resistance | High | Low |

Elasticity | High | Limited |

Note: Always ask for up-to-date compliance documents. Good suppliers will give you test reports and certificates. This helps you avoid fake silicone and keeps your projects safe.

Spotting Fake Silicone Insulated Cables

Smell and Texture Issues

You can use your senses to find fake silicone insulated cables. Real silicone rubber insulated cables do not smell strong. If you smell chemicals, it might be fake. Genuine silicone rubber feels smooth and soft. When you touch the cable, it should not feel sticky. It should not feel oily. Some fake silicone insulated cables use cheap stuff. These can leave a mark on your hands. Always check how the cable feels. Real silicone rubber insulated cables bend easily. They do not get stiff when it is cold.

Tip: Use your nose and hands to check. If the cable smells bad or feels strange, do not use it.

Insulation Defects

Look closely at the insulation on silicone insulated cables. Real silicone rubber insulated cables have thick, even insulation. You should not see bubbles or cracks. There should not be thin spots. If you see holes or rough places, the cable may be fake. Bad insulation can cause electrical trouble or fires. Always check the ends of the cable. Sometimes, fake silicone insulated cables have insulation that peels or splits.

Look for smooth and even insulation.

Stay away from cables with cracks or holes.

Make sure the insulation does not peel off.

Labeling Inconsistencies

Labels help you know if silicone insulated cables are real. You should see clear printed words on the cable. Look for cable type, voltage rating, and temperature range. If the label is missing or faded, it might be fake. If there are spelling mistakes, it could be fake. Some fake silicone insulated cables copy real labels. They use the wrong font or size. Always compare the label to a trusted sample. You can ask the supplier for proof.

What to Check | Real Silicone Cable | Fake Cable Example |

Label Clarity | Clear and easy to read | Blurry or missing |

Info Accuracy | Correct specs and ratings | Wrong or missing details |

Spelling/Grammar | No mistakes | Errors or odd symbols |

Note: Checking the label carefully can help you avoid buying fake silicone insulated cables.

Verification Methods for Silicone Cable

Simple At-Home Tests

You can do easy tests at home to check your silicone cable. These steps help you find real silicone and avoid fake ones.

Visual Inspection: Look for clear markings and factory details. Check for certifications on the wire. The insulation should look smooth. It should be the same thickness everywhere.

Tactile Testing: Bend the cable gently. Silicone rubber feels soft and stretchy. It should not crack or feel hard.

Copper Quality Check: Peel back the insulation. Rub the copper wire on white paper. If you see black marks, the copper is not pure.

Weight Measurement: Weigh the cable. Real silicone cables have a normal weight for their size.

Price Evaluation: If the price is very low, the cable might be fake.

Tip: Try these tests before you buy or use silicone cable. They help you avoid problems with bad insulation or fake materials.

Documentation and Traceability

Always ask your supplier for documents. Good suppliers give proof that their silicone cables are real and safe.

Ask for audit reports and certifications for your needs, like food-grade or medical use.

Request Certificates of Analysis, batch traceability, and test reports. These show things like how strong the insulation is and how much it stretches.

Use random checks and third-party inspections before shipping. This helps you find problems early.

Note: Documents help you track where your silicone cable comes from. They also show the insulation meets safety rules.

Trusted Suppliers

Pick suppliers with a good reputation. Trusted suppliers sell real silicone cables and give all needed documents. They answer your questions and help you check the insulation. You can ask for samples and compare them with real silicone rubber cables. Good suppliers follow new standards and update their products.

What Trusted Suppliers Offer | Why It Matters |

Certifications | Proves cable authenticity |

Test Reports | Shows insulation quality |

Batch Traceability | Tracks silicone cable history |

Tip: Get to know your supplier. This makes it easier to get help and makes sure you always get real silicone products.

2026 Trends in Silicone Cable Authentication

New Verification Technologies

In 2026, new ways help you check silicone cables. Smart holographic labels now have RFID chips inside. These labels are hard for fakers to copy. RFID helps you find and track cables, even if you cannot see the label. You can scan the label with your phone or a reader. The system tells you if the cable is real or fake. These tools keep fake silicone cables out of your work. You get better safety and can trust your cables more.

Tip: Always look for holographic labels and RFID chips when you buy silicone cables. These features help protect you from fake products.

Regulatory Updates

Rules for silicone cable change a lot. In 2026, you need to check new safety and environmental rules. Groups like UL and IEC make stricter rules for silicone rubber. You must check if your cables follow RoHS and CE rules. These new rules help you use safer cables and protect nature. You should ask your supplier for the newest certificates and test reports.

Regulatory Body | What to Check in 2026 |

UL | New safety standards |

IEC | New environmental rules |

RoHS | Limits on harmful materials |

CE | Rules for EU markets |

Market Awareness

You need to be careful in the silicone cable market. Many sellers offer cables, but some are not real. You learn to spot fake cables by checking labels and certifications. You also look at the supplier’s reputation. You read news about scams and fake products. You join online groups to share tips and stories. You help others by reporting fake silicone cables. The market gets smarter as more people learn how to check for real silicone rubber cables.

Note: Staying alert helps you make good choices and keeps your equipment safe.

You can find real silicone cable if you do these things:

Make sure the cable works from −60°C to +180°C.

Look for tinned stranded copper inside the cable.

Check if the voltage rating is close to 300/500V.

Measure how thick the cable is and how much it bends.

Look at the silicone insulation and the outside cover.

Learn about new rules and certifications. This helps you stay away from fake cables and keeps your things safe. Make a checklist before you buy any cable. Tell us your ideas or stories in the comments!

FAQ

How can you tell if a silicone cable is fake?

Look for stiff insulation, faded colors, and missing certification marks. Fake cables often smell like chemicals. You should check for clear labels and smooth, flexible surfaces.

What certifications should you check on silicone cables?

You should look for UL, CSA, HAR, or VDE marks. These show the cable passed safety tests. Ask your supplier for certificates if you do not see these marks.

Can you test silicone cable at home?

Yes! Bend the cable to check flexibility. Rub the copper wire on paper to see if it leaves black marks. Real silicone feels soft and does not crack.

Why do temperature ratings matter for silicone cables?

Temperature ratings show how much heat the cable can handle. You need cables rated for at least 180°C for most jobs. Low ratings mean the cable may fail in hot places.

What should you do if you suspect a cable is counterfeit?

Stop using the cable. Contact your supplier and ask for test reports. Share your experience with others to help them avoid fake products.