Waterproof connectors are special electrical connectors. They keep water out. This protects your connections from moisture and dirt. You need these connectors for electronics in wet places. They help your devices work safely in damp areas. More than 30% of equipment failures happen because moisture gets in. This includes wiring junctions and connectors.

Pick waterproof connectors for wet places. This helps prevent water damage.

Use waterproof boxes, electrical tape, silicone, or epoxy for extra safety.

These steps lower the risk of failure. They help your devices last longer.

Key Takeaways

Waterproof connectors keep water and dirt away from wires. This helps stop equipment from breaking.

Pick connectors with the right IP ratings for your area. This gives the best protection from water and dust.

Check and fix connectors often to make them last longer. Change seals when needed to keep them working well.

Use sealing materials like silicone and rubber gaskets. These help make your connections more waterproof.

Choose the right waterproof connector for your job. Think about if it is for outside, factories, or special uses.

Waterproof Connectors Features

Sealing Materials

You want your electrical connections to stay dry and safe. The right sealing materials help with this. Manufacturers use special compounds to keep water and dirt away from the metal parts inside waterproof connectors. These materials also stop rust and corrosion.

Here is a table showing common sealing materials and how well they work:

Sealing Material | Effectiveness Rating | Notes |

Thermoplastic elastomer | IP67 | Ideal for aircraft environments |

Nylon | IP65 | Cost-effective for moist environments |

Glass-filled polyester | IP65 | Durable with special seals for protection |

You often see silicone, grease, and petroleum-based materials in waterproof connectors. Silicone grease is a strong water blocker. It seals and insulates the connection. This keeps moisture and dirt out. Grease covers the metal contacts and stops corrosion. This barrier keeps the contacts clean and helps them last longer. Dielectric grease also seals, waterproofs, and lubricates the connection. It does not block electricity, but it protects the metal from water and dirt.

Tip: Always check the sealing material before you pick a connector. The right material can help your device last longer.

IP Ratings

You need to know how much protection your connector gives against water and dust. The IP (Ingress Protection) rating tells you this. Each number in the rating means something. The first number shows how well the connector keeps out dust. The second number shows how well it keeps out water.

Here is a table that explains the most common IP ratings for waterproof connectors:

Rating | Dust Protection | Water Protection | Description |

IP67 | 6 (dust-tight) | 7 (up to 1m for 30 mins) | Temporary immersion in water, suitable for brief exposure. |

IP68 | 6 (dust-tight) | 8 (beyond 1m, specifics vary) | Continuous immersion in water, ideal for demanding applications. |

IP69K | 6 (dust-tight) | 9K (high-pressure jets) | Protection against high-pressure and high-temperature water jets, suitable for industrial cleaning. |

If you use a connector with an IP67 rating, it works for short dips in water. IP68 connectors work even when left underwater for a long time. IP69K connectors can handle strong water jets and high heat. You often see these in places that need heavy cleaning, like factories.

Note: Always match the IP rating to your environment. If you expect lots of water or dust, pick a higher rating for better protection.

How They Work

Water Ingress Prevention

You want your electrical connections to stay dry. This is important in tough places. Waterproof connectors use smart ways to keep water out. They have strong seals and special materials. These block moisture from getting inside. You often find O-rings, rubber gaskets, and sealants inside. These parts make a tight barrier. Water and dust cannot reach the metal contacts.

Here is a table showing some common ways to stop water:

Mechanism | Description |

Structural Tightness | O-rings and gaskets have many layers. They make a strong wall against water and dust. |

Material Protection | Silicone, fluororubber, and polyurethane fight water and chemicals. They keep the connector safe. |

Sealing Structure Design | Parts fit tightly and seals are built in. When you connect them, they squeeze together and block water. |

Waterproof Materials Choice | Some materials do not soak up water. They also resist chemicals. These last longer and work well. |

Waterproof Testing | Each connector gets tested with water pressure and soaking. This makes sure it works right. |

You can use extra ways for more protection. Heat shrink tubing wraps around wires and connectors. It gets tight when heated. Liquid electrical tape makes a waterproof layer over odd shapes. These methods help keep connections safe in wet places.

Design Elements

The design of waterproof connectors helps keep water out. Makers pick materials like rubber and silicone. These seal well and keep the connection safe. Many connectors have gaskets or rubber O-rings inside. These parts squeeze together when you plug in the connector. This makes a tight seal.

Key design features include:

Sealing gaskets block water and dirt from getting in.

Locking parts hold the connector together, even if it shakes.

Tight parts press the seals in place for more safety.

Tip: Always look for these features when you choose a connector. Good design gives better protection and helps your devices last longer.

Waterproof connectors keep electricity flowing by using smart designs. You can feel safe knowing your connections stay dry, even in tough places.

Applications

Outdoor Use

When you work outside, you need strong connections. Rain and dust can hurt regular connectors. Temperature changes also cause problems. Waterproof connectors protect your devices. They help your devices work in bad weather.

Some outdoor uses are:

Outdoor LED displays need steady power. Waterproof connectors keep them bright in storms.

Cruise ship lights use these connectors. They stop water from causing short circuits.

Shipyards use them to protect heavy equipment from saltwater.

You also see them in surgical rooms and transport units. Safety and reliability are very important there.

If you look at waterproof connectors and standard connectors, you see big differences:

Feature | Waterproof Connectors | Standard Connectors |

Environmental Resistance | Made for tough outdoor conditions | Can be damaged by weather |

Sealing and Durability | Strong seals stop water getting in | Weak seals let water cause problems |

Safety Standards | Meet CQC, UL, TUV rules | May not meet strict safety rules |

Waterproof Rating | Usually IP65 or higher | No waterproof rating |

Tip: Pick connectors that fit your environment. Outdoor places need extra protection.

Industry Examples

Many industries need good connections. Waterproof connectors work where water, dust, or chemicals can cause trouble.

Industry | Reason for Reliance |

Marine | Needed for navigation and communication in tough places. |

Outdoor Lighting | Stops moisture and dust, keeps lights working. |

Agriculture | Helps machines work in wet and dusty places. |

Construction | Stops equipment from breaking due to water and dirt. |

Telecommunications | Keeps signals strong in outdoor setups. |

Automotive | Needed for car systems where space and sealing matter. |

Medical | Protects sensitive tools from water and dirt. |

You find these connectors in underwater vehicles and outdoor cameras. Marine equipment uses them too. Factories use them in places with steam and strong cleaning. In farming and building, they help machines keep working, even when things get tough.

Types of Waterproof Connectors

Circular

Circular connectors are used in tough places. The pins are set in a circle. This shape makes them strong and easy to seal. You see them in factories and military gear. O-rings and gaskets keep water out. Their round shape helps them handle stress. Amphenol is a brand that makes these for hard jobs. You can use circular connectors for robots, machines, and outdoor lights.

Rectangular

Rectangular connectors fit more pins in less space. The pins are lined up in a grid. This works well for cars and network devices. You find them in computers and control panels too. It is harder to seal rectangular shapes. Engineers add extra features to block water. Delphi Metri-Pack is a top brand for these connectors. They use triple-rib silicone seals to keep water out. You can put them in fast, sometimes with one step. You do not need to twist wires.

Specialty Types

Specialty connectors are made for special jobs. Some work underwater or in medical tools. Others handle high voltage or strong chemicals. You see them in solar panels and underground wires. Some can handle 1000 volts or more. They use thick covers and special stuff to stay safe.

Here is a table to compare circular and rectangular connectors:

Feature | Circular Connectors | Rectangular Connectors |

Pin Configuration | Pins in circles, fewer pins overall | More pins in a grid |

Common Applications | Factory controls, military gear | Car electronics, network devices |

Environmental Protection | Sealed well with O-rings and gaskets | Needs extra work to seal |

Durability and Strength | Strong and round, handles stress | Easy to use, may have weak spots |

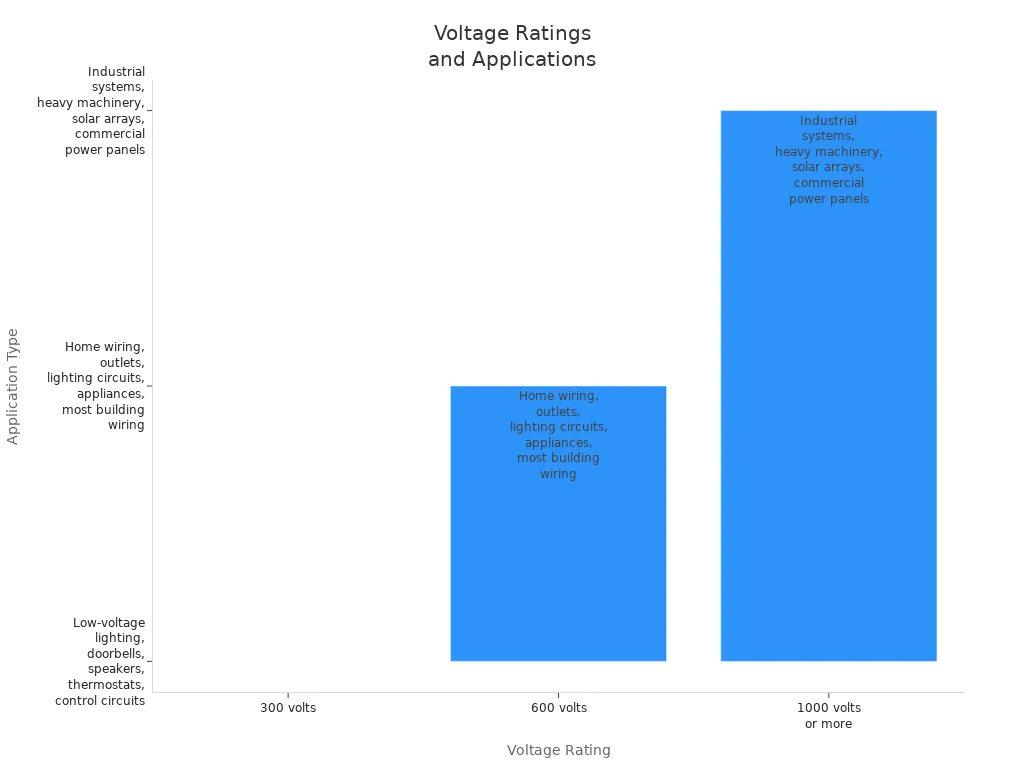

You should check voltage ratings and wire sizes. Here is a quick guide:

Voltage Rating | Application |

300 volts | Lights, doorbells, speakers, thermostats, controls |

600 volts | Home wires, outlets, lights, appliances, building wiring |

1000 volts or more | Big machines, solar panels, power panels |

Tip: Always check voltage and current ratings before using a connector. This keeps your devices safe.

You can find waterproof connectors in many places: 1. Factory robots and controls. 2. Medical tools that must stay dry. 3. Outdoor lights and electronics.

Nylon and plastic do not break down easily. Thick connectors and wide gaps mean higher voltage ratings. Some connectors are small for tight spaces. Others have thick covers for tough jobs.

Benefits and Selection

Advantages

You get many benefits when you use waterproof connectors. These connectors keep water out, so your devices stay safe. They protect the metal parts inside from rust and corrosion. You can use them in places with rain, snow, or even saltwater. They last longer because they resist shocks and vibrations. You do not have to worry about temperature changes because they work in hot and cold weather. You can clean them with strong water jets, which helps in places that need to stay very clean.

They create a watertight seal to block liquid.

They have strong locking parts that resist shaking.

They keep working in extreme heat or cold.

They stop rust, even with chemicals or salt.

You can clean them with pressurized water.

Using waterproof connectors lowers the risk of short circuits and failures. Your electrical systems stay safe and reliable, even outdoors.

Choosing Tips

You need to pick the right connector for your job. Think about where you will use it. Will it face rain, heat, or salt? Check the voltage and current it must handle. Look at the materials. Some work better in saltwater, while others resist heat. Make sure the connector fits your wires and devices. Always check the IP rating for the level of protection.

Factor | What to Check |

Environment | Moisture, temperature, salt, vibration |

Electrical Specs | Voltage, current, insulation |

Material | Corrosion and heat resistance |

Sealing/IP Rating | Higher numbers mean better protection |

Compatibility | Size and mounting style |

Tip: Follow the maker’s instructions for installation. This helps the seal work well and keeps water out.

Maintenance

You should check your connectors often. Look for cracks, rust, or water inside. Clean the contacts every few months with a soft cleaner. In wet or salty places, check them more often. Replace rubber seals every 18 to 24 months, even if they look fine. Always test the connection to make sure it works right.

Inspect monthly for worn seals or color changes.

Clean contacts every three months.

In coastal areas, check more often for salt damage.

Replace seals every 18–24 months.

Test connections to catch hidden problems early.

Regular care helps your connectors last longer and keeps your devices safe.

You need strong connections in hard places. Waterproof connectors help your devices stay safe and work well.

They keep electricity and signals working, even if you clean them a lot or they get wet.

You can use them in dusty or wet places, like on conveyor belts.

Think about what you need before picking a connector. The right one keeps you safe and your devices working every day.

FAQ

What does "IP68" mean for waterproof connectors?

IP68 means your connector blocks dust and can stay underwater for long periods. You get strong protection for outdoor or wet environments.

Can you use waterproof connectors for outdoor lighting?

You can use waterproof connectors for outdoor lights. They keep water out and help your lights work in rain or snow.

How do you check if a connector is waterproof?

Look for an IP rating label.

Check for rubber seals or O-rings.

Read the product description for waterproof features.

Do waterproof connectors need special maintenance?

Task | How Often |

Inspect seals | Every month |

Clean contacts | Every 3 months |

Replace seals | Every 18–24 months |

You keep your connectors working longer with regular care.