Reliable wiring harnesses are critical components in modern vehicles, drones, and LED devices, serving as the backbone for efficient power distribution and signal transmission. As technology advances, these systems become increasingly complex, requiring wiring solutions that can deliver consistent electrical performance while withstanding environmental stresses such as vibration, temperature fluctuations, and moisture.

A dependable wiring harness ensures that power flows smoothly to various components, while signals are transmitted accurately without interference or loss. This reliability directly impacts the overall functionality, safety, and longevity of equipment across diverse industries.

In vehicles, drones, and LED lighting systems, the quality of wiring harnesses influences everything from engine control and flight stability to lighting performance and energy efficiency. Understanding the role of reliable wiring harnesses is essential for manufacturers and users aiming to maximize device performance and minimize downtime.

Key Factors Affecting Wiring Harness Performance

The performance and reliability of wiring harnesses depend on several critical factors. Understanding these elements helps ensure the selection and manufacturing of harnesses that meet the rigorous demands of vehicles, drones, LED devices, and other applications.

1. Conductor Material and Structure

The choice of conductor material significantly influences electrical conductivity, flexibility, and durability. Copper is the most commonly used material due to its excellent conductivity and corrosion resistance. In some cases, tinned copper is preferred to further enhance corrosion resistance, especially in harsh environments.

Additionally, the structure of the conductor—whether solid or stranded wire—affects flexibility and resistance to fatigue. Stranded wires are favored in applications requiring frequent movement or vibration resistance, such as drones and automotive systems.

2. Insulation and Sheath Materials

The insulation layer protects the conductor from electrical shorts, mechanical damage, and environmental factors. Materials such as PVC, polyethylene, silicone, and Teflon are commonly used, each offering specific properties like heat resistance, flexibility, or chemical resistance.

The outer sheath provides additional protection against abrasion, moisture, UV exposure, and chemicals. Selecting appropriate insulation and sheath materials tailored to the operating environment is crucial for maintaining harness integrity and safety.

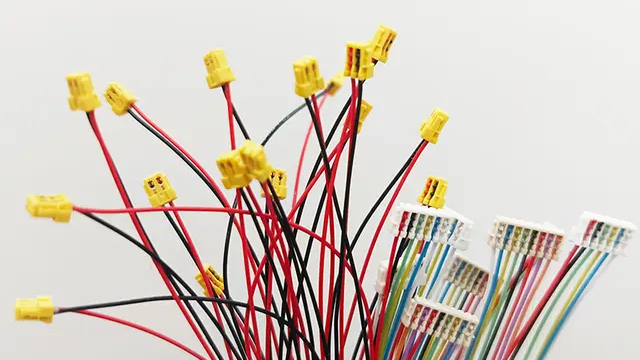

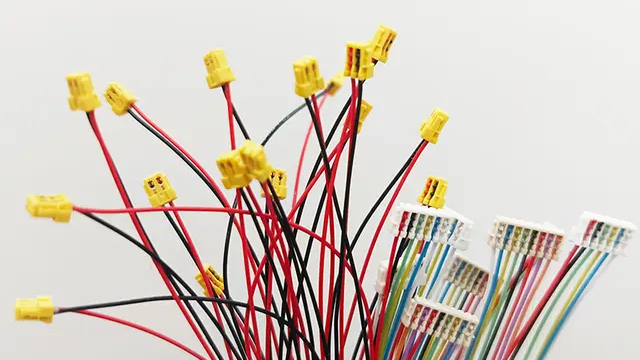

3. Connectors and Assembly Techniques

Connectors serve as the critical interface points in a wiring harness, enabling secure and reliable electrical connections. High-quality connectors with proper sealing, locking mechanisms, and corrosion resistance contribute to long-term performance.

Assembly techniques, including soldering, crimping, and overmolding, affect the mechanical strength and electrical continuity of connections. Precision assembly and rigorous quality control ensure that the wiring harness can withstand operational stresses without failure.

Special Requirements for Automotive Wiring Harnesses

Automotive wiring harnesses must meet a unique set of performance standards due to the demanding conditions within vehicles. These harnesses are responsible for delivering power and transmitting signals between critical systems—such as the engine, lighting, safety features, and infotainment. To ensure reliable operation throughout a vehicle’s lifecycle, automotive wiring harnesses must possess specific qualities that enable them to function in harsh and variable environments.

1. Heat Resistance

Under-the-hood environments can reach extremely high temperatures, especially near the engine and exhaust systems. As a result, automotive harnesses must use heat-resistant insulation materials like cross-linked polyethylene (XLPE), silicone, or Teflon. These materials prevent insulation breakdown, electrical shorting, or deformation that could result from prolonged exposure to heat.

2. Vibration Resistance

Vehicles constantly experience vibration and mechanical movement while in operation. To withstand these conditions, wiring harnesses are designed with flexible conductors and secure routing paths that reduce mechanical strain. Additional features such as vibration-damping mounts and protective sleeves help prevent wire fatigue and connector failure.

3. Corrosion Protection

Automotive harnesses are often exposed to moisture, road salts, oil, and chemicals. To combat corrosion, manufacturers use tinned copper wires, sealed connectors, and protective coatings. These materials and designs help maintain conductivity and prevent oxidation, even in extreme weather or wet conditions.

4. Stable Power and Signal Transmission

Modern vehicles rely heavily on electronics for safety, performance, and comfort. From engine management systems to driver-assistance features, stable signal and power transmission is critical. Automotive wiring harnesses must minimize signal interference and power loss, using shielding, twisted pair cables, and precise connector interfaces to ensure flawless communication across all systems.

Wiring Harness Requirements for Drones and LED Devices

Wiring harnesses designed for drones and LED systems must address specific engineering challenges such as weight constraints, flexibility in routing, and support for fast and reliable signal transmission. These systems demand high performance from compact and lightweight electrical solutions, making advanced harness design essential.

1. Lightweight and Flexible Construction

Drones, in particular, are highly sensitive to weight. Every additional gram can reduce flight time and maneuverability. Therefore, drone wiring harnesses must be constructed using lightweight conductors and minimal insulation bulk, while still maintaining mechanical strength and safety. Flexibility is also crucial—tight spaces within drone frames require harnesses that can bend and conform without putting stress on solder joints or connectors.

Similarly, LED systems—especially in architectural or automotive applications—often involve curved surfaces or confined installation spaces. A flexible harness allows easy routing and installation in creative or compact configurations, improving both functionality and aesthetic design.

2. High-Speed Signal Transmission Support

Modern drones rely heavily on high-speed data for real-time video feeds, GPS, gyroscopic controls, and sensor fusion. To ensure uninterrupted and accurate signal flow, drone wiring harnesses often use shielded cables, twisted pairs, and low-capacitance insulation that reduce signal loss and electromagnetic interference (EMI).

In LED lighting systems, especially RGB and smart lighting setups, harnesses must carry precise control signals for synchronized dimming, color shifting, or pattern effects. High signal integrity ensures consistent brightness, fast response times, and overall system reliability.

How to Ensure the Reliability of Wiring Harnesses

Ensuring the reliability of a wiring harness is essential for the safe and uninterrupted operation of modern machines and devices. Whether in vehicles, drones, battery systems, or LED applications, a failure in the harness can lead to power loss, signal disruption, or even safety hazards. The following practices are key to achieving consistent, high-performance wiring harnesses.

1. Quality Control Processes

A strict quality control (QC) system is fundamental to reliable harness production. From incoming raw material inspection to final product testing, each step must follow precise procedures:

Material inspection: All wires, connectors, insulation materials, and accessories are checked for compliance with specifications.

Process monitoring: Crimping, soldering, routing, and bundling are monitored to maintain consistency.

Visual and mechanical inspection: Finished harnesses undergo checks for correct assembly, labeling, and mechanical strength.

Well-documented QC processes reduce the risk of defects and improve long-term performance across various use cases.

2. Certifications and Testing Standards

Reliable wiring harnesses must conform to recognized industry standards and certifications to ensure safety and interoperability:

ISO 9001 / IATF 16949: Quality management standards for automotive and industrial applications.

UL / CE certification: Verifies that materials and finished products meet safety regulations.

Environmental and functional testing: Includes resistance to temperature, vibration, moisture, corrosion, abrasion, and electrical performance (e.g., continuity, insulation resistance, dielectric strength).

Testing under simulated operating conditions ensures that the harness can withstand real-world environments.

Conclusion

Ensuring the long-term reliability of wiring harnesses starts with choosing the right manufacturing partner. A qualified and experienced supplier can provide expert engineering support, use high-grade materials, follow strict quality control processes, and conduct comprehensive testing to meet industry standards. This guarantees that each harness delivers consistent performance, safety, and durability.

Dongguan Suyi Electronics Co., Ltd. is a trusted manufacturer specializing in custom wiring harnesses for a wide range of machines and equipment—including automotive, drone, battery, and LED applications. With a strong commitment to precision and reliability, Suyi delivers solutions that meet your exact specifications and performance needs.

Explore their capabilities and discover how they can support your project by visiting www.suyiwiringharness.com. For custom inquiries or technical consultation, don’t hesitate to contact their expert team today.