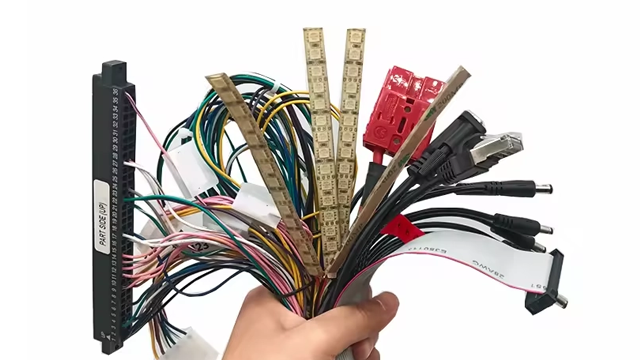

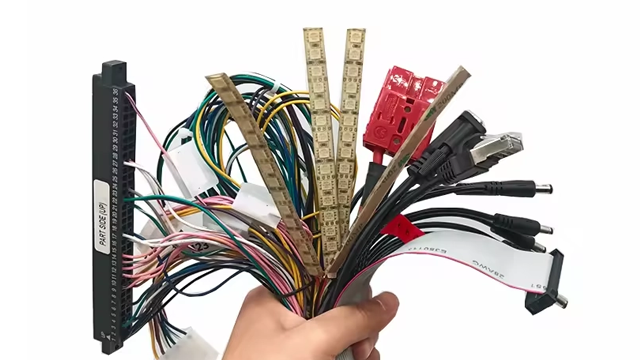

A wiring harness is a structured and organized assembly of electrical wires, connectors, terminals, and protective coverings that transmit power and signals within a machine or electronic system. Its core function is to ensure safe, reliable, and efficient electrical communication between different components—whether in vehicles, drones, battery packs, or LED lighting systems.

By bundling multiple wires into a single, compact unit, a wiring harness simplifies installation, reduces clutter, and minimizes the risk of short circuits or loose connections. It routes electrical energy or control signals precisely to the components where they’re needed, supporting everything from ignition systems in cars to sensor arrays in drones or current regulation in LED drivers.

Each wiring harness is custom-designed based on its intended application, taking into account power load, environmental conditions, mechanical stress, and space limitations. The quality of its materials and design directly impacts the performance, safety, and lifespan of the entire system it supports.

How Automotive Wiring Harnesses Work

Automotive wiring harnesses are essential for modern vehicles, acting as the nervous system that connects various components to both power sources and control units. Their primary function is to transmit electrical power and signals throughout the vehicle, ensuring seamless operation of mechanical, electrical, and electronic systems.

Connecting Power Sources to Functional Modules

The wiring harness links the car battery and alternator to all power-dependent components, including the ignition system, fuel injection system, lighting, power windows, and infotainment units. It ensures that each module receives the correct voltage and current to perform its function reliably.

Each wire within the harness is carefully routed and insulated, minimizing the risk of overheating or electrical interference. Fuses and relays are often integrated into the harness to manage overload protection and circuit switching.

Signal Transmission and System Control

Beyond power distribution, automotive harnesses carry control signals between the vehicle’s electronic control units (ECUs), sensors, and actuators. These signals are critical for real-time operations such as engine timing, airbag deployment, anti-lock braking (ABS), parking assistance, and more.

To maintain signal integrity, automotive harnesses often include twisted pairs, shielding, or grounding wires that prevent electromagnetic interference (EMI). This design ensures reliable data transmission in even the most electrically noisy environments.

How Drone Wiring Harnesses Work

Drone wiring harnesses are specifically engineered to support compact, lightweight aerial platforms that rely on fast, precise communication and stable power delivery. These harnesses form the backbone of a drone’s electrical system, enabling it to perform complex flight tasks with stability, efficiency, and safety.

Supporting Multi-Sensor and Control Systems

Modern drones are equipped with multiple subsystems—including GPS modules, IMUs (inertial measurement units), cameras, flight controllers, motor ESCs (electronic speed controllers), and communication modules. The wiring harness connects all of these components to the drone’s central processing unit and battery system.

Each wire or signal path within the harness is designed to transmit power or data with minimal interference and voltage drop. High-density connectors and precision crimping ensure secure connections in a small footprint, supporting the space-saving design required by UAVs.

Enabling Stable Flight and Communication

To maintain flight stability, the drone’s flight controller must process real-time data from sensors and issue immediate commands to the motors. The wiring harness plays a key role in delivering these high-speed control signals reliably, often incorporating shielded or twisted-pair cables to minimize electromagnetic interference (EMI).

Additionally, drones rely on constant communication with ground control stations. The harness routes signals between onboard radios or transmission units and antennas, enabling real-time telemetry, video transmission, and remote navigation.

How Battery Wiring Harnesses Work

Battery wiring harnesses are vital components in power systems—especially in electric vehicles, energy storage units, and portable electronics. These harnesses ensure the safe and efficient flow of electrical current, while also supporting real-time monitoring and safety protection features.

Current Transmission and Status Monitoring

The primary role of a battery wiring harness is to transmit high-current power from the battery cells to the load—such as a motor, inverter, or control board. These harnesses use thick-gauge, low-resistance conductors to handle high power demands while minimizing energy loss and heat generation.

In addition to power delivery, battery harnesses are integrated with voltage sensing lines, temperature sensors, and communication cables. These lines transmit key data to the Battery Management System (BMS), enabling real-time monitoring of the battery’s:

This information is crucial for optimizing performance and preventing battery damage.

Protection and Safety Management

Given the high energy levels involved, battery harnesses must also provide robust safety mechanisms. They incorporate insulated sheathing, fuse protection, and secure connectors to prevent:

In advanced battery packs, harnesses may include EMI shielding or be embedded with smart safety modules to shut down circuits during failure events. These safety features help extend battery life and ensure compliance with global safety standards.

How LED Wiring Harnesses Work

LED wiring harnesses are essential components that power and control modern lighting systems, from automotive headlights and signage to architectural installations and smart lighting networks. These harnesses are designed not only to deliver consistent electrical power but also to enable precise lighting control, all while maintaining flexibility and durability in demanding environments.

Power Supply and Lighting Control

The primary function of an LED wiring harness is to deliver low-voltage DC power from a driver or power supply to the LED modules. Reliable power delivery is critical to ensure consistent brightness, prevent flickering, and extend the lifespan of LED components.

In addition to power, the harness also transmits control signals for functions such as:

Dimming

Color temperature adjustment

RGB or addressable lighting effects

Synchronization with sensors or smart controllers

These control signals are often sent via PWM (Pulse Width Modulation), DALI, DMX, or other lighting communication protocols, requiring the harness to maintain signal integrity across multiple zones or fixtures.

Flexible Routing and Environmental Protection

LED lighting is often installed in tight, curved, or exposed areas—such as automotive interiors, display panels, or outdoor signage. Therefore, LED wiring harnesses must be:

Flexible, allowing easy routing through compact or irregular spaces

Durable, with insulation and sheathing that resist UV radiation, moisture, heat, and chemical exposure

Slim and discreet, especially in consumer-facing or decorative lighting applications

Some harnesses also include snap-in connectors, waterproof plugs, or quick-release terminals for easier maintenance and installation.

Conclusion: Tailored Wiring Harnesses for Optimized Performance Across Applications

While the core purpose of a wiring harness is to transmit power and signals, the functional demands vary significantly across different applications. In automotive systems, harnesses must endure high heat, vibrations, and corrosion. In drones, they need to be lightweight, compact, and vibration-resistant. Battery harnesses must support high current flow while enabling real-time monitoring and safety management. Meanwhile, LED harnesses must allow for flexible routing and signal integrity in control systems.

These varying requirements highlight the importance of customized wiring harness design. A one-size-fits-all approach simply cannot meet the specific needs of complex machinery or advanced electronic devices. Instead, harnesses must be engineered with careful consideration of the operating environment, electrical load, physical constraints, and long-term reliability.

By investing in custom wiring harness solutions, manufacturers can improve system performance, enhance safety, reduce maintenance costs, and increase product lifespan.

For high-quality, application-specific wiring harnesses, Dongguan Suyi Electronics Co., Ltd. offers professional design, production, and testing services to meet your unique needs. Visit www.suyiwiringharness.com to learn more or contact their team for tailored support.