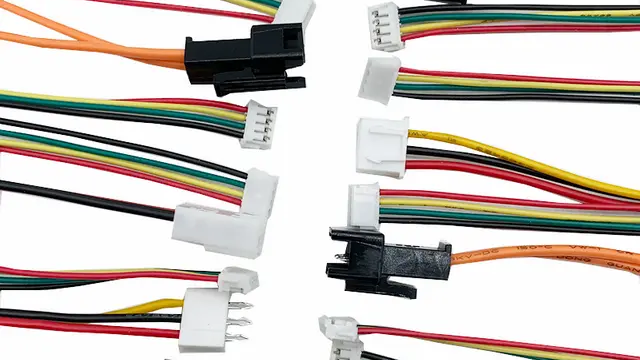

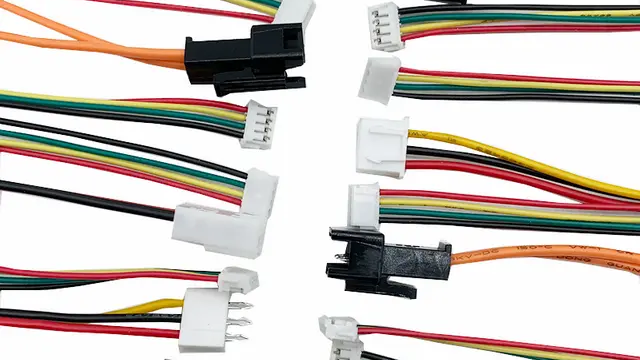

A wiring harness is an essential component in modern machinery and electronic equipment. It is a carefully organized assembly of wires, cables, connectors, and terminals that facilitates the reliable transmission of electrical power and signals throughout a device. By bundling individual wires into a single, structured unit, wiring harnesses simplify installation, improve safety, and enhance the overall performance of electrical systems.

Wiring harnesses are used extensively across a wide range of machines and equipment. In automobiles, they connect everything from engine control units to lighting systems, ensuring smooth vehicle operation. In drones, wiring harnesses manage power distribution and communication between motors, sensors, and flight controllers, enabling stable flight and precise control. Battery systems rely on specialized wiring harnesses to handle high-current power transmission and monitoring functions, critical for safety and efficiency. LED lighting systems use harnesses to deliver power and control signals reliably while supporting flexible and compact designs.

Understanding the diverse applications of wiring harnesses highlights their importance in keeping machines and equipment powered, connected, and functioning optimally in various industries.

Wiring Harness Applications in Automobiles

In the automotive industry, wiring harnesses are fundamental to the functionality, safety, and efficiency of modern vehicles. They serve as the central nervous system, connecting various electrical and electronic components that power and control a wide range of systems.

Powertrain and Engine Control Systems

Wiring harnesses transmit power and signals between the vehicle’s battery, engine control units (ECUs), sensors, and actuators. These connections are critical for managing fuel injection, ignition timing, emission controls, and other engine functions that optimize performance and reduce environmental impact.

Lighting Systems

Automotive wiring harnesses also support the vehicle’s complex lighting arrangements, including headlights, taillights, brake lights, turn signals, and interior lighting. Reliable wiring ensures consistent illumination, enhancing both driver visibility and safety on the road.

In-Vehicle Electronics

Modern cars feature numerous electronic systems such as infotainment centers, GPS navigation, climate control, airbags, and advanced driver-assistance systems (ADAS). Wiring harnesses connect these modules seamlessly, enabling smooth communication and operation.

Durability and Heat Resistance Requirements

Automotive wiring harnesses must endure harsh conditions, including extreme temperatures, vibrations, moisture, and exposure to chemicals. Therefore, materials used in automotive harnesses prioritize durability and heat resistance to maintain electrical integrity over the vehicle’s lifetime. Proper insulation, protective sheathing, and secure connectors help prevent failures caused by wear, corrosion, or thermal stress.

Key Features of Wiring Harnesses in Drones

Wiring harnesses in drones are engineered to meet the unique challenges posed by aerial applications. Due to drones’ compact size, dynamic flight conditions, and critical performance demands, their wiring systems require specialized design considerations.

Lightweight Construction

Weight is a crucial factor in drone design, directly affecting flight time, maneuverability, and payload capacity. Drone wiring harnesses use lightweight materials and streamlined designs to minimize added weight without compromising durability or functionality. This lightweight construction helps maximize battery efficiency and overall flight performance.

High Reliability

Drones often operate in variable and sometimes harsh environments, such as high winds, temperature fluctuations, and electromagnetic interference. Wiring harnesses for drones must therefore be highly reliable to ensure continuous power delivery and stable signal transmission to critical components like motors, sensors, cameras, and flight controllers. Robust connectors and superior insulation materials reduce the risk of electrical failures during flight.

High-Density Connections

Space constraints in drones require harnesses to support high-density wiring configurations. This involves packing numerous wires and connectors into a compact, organized bundle to connect multiple subsystems efficiently. Advanced manufacturing techniques and precision assembly enable high-density harnesses that maintain signal integrity and ease of installation.

Vibration Resistance

Drones experience constant vibrations during operation from motors and aerodynamic forces. Wiring harnesses are designed with vibration resistance in mind, using flexible cables, secure fastenings, and strain relief components to prevent wire fatigue, disconnections, or damage. This ensures the drone’s electrical system remains intact and reliable throughout its flight cycles.

Wiring Harness Applications in Battery Systems

Battery systems, especially those used in electric vehicles (EVs), energy storage units, and portable electronics, depend heavily on specialized wiring harnesses to ensure efficient power delivery and system safety. These harnesses serve as the vital link between battery cells, management systems, and external devices.

Power Transmission and Signal Monitoring

Wiring harnesses in battery systems are responsible for transmitting high currents safely from the battery pack to the device or vehicle’s powertrain. Simultaneously, they carry low-voltage signals used for battery management and monitoring, such as temperature sensors, voltage measurement points, and state-of-charge indicators. This dual functionality requires the harness to handle both high power and sensitive signal lines without interference.

Safety Protection Requirements

Given the high voltages and currents involved, battery wiring harnesses must adhere to stringent safety standards. They incorporate robust insulation and protective coverings to prevent short circuits, electrical shocks, and fire hazards. Additionally, wiring harnesses often feature secure locking connectors and fail-safe designs to withstand vibrations, thermal cycling, and potential mechanical impacts.

Special attention is also paid to thermal management, ensuring that wires can endure temperature variations and dissipate heat effectively. This prevents insulation degradation and maintains long-term system reliability.

Wiring Harness Applications in LED Systems

Wiring harnesses in LED lighting systems play a crucial role in connecting LED fixtures to power sources and control units, ensuring consistent illumination and flexible installation options across various applications—from architectural lighting to automotive and commercial displays.

Connecting LED Fixtures and Control Systems

The wiring harness serves as the essential pathway that delivers electrical power from the source to individual LED modules while also transmitting control signals for dimming, color changes, and synchronization. This ensures that LED lights operate smoothly and respond accurately to user commands or automated control systems.

Corrosion Resistance and Flexible Wiring Needs

LED lighting systems are often exposed to environmental factors such as moisture, dust, and temperature fluctuations, which can degrade wiring integrity over time. Therefore, wiring harnesses designed for LED applications use corrosion-resistant materials and robust protective coatings to withstand harsh conditions, especially in outdoor or automotive environments.

Additionally, many LED installations require flexible wiring harnesses that can bend and twist to fit compact or curved spaces without compromising electrical continuity. This flexibility supports innovative lighting designs and easy maintenance.

Conclusion: The Importance of Customized Wiring Harnesses Across Industries

In today’s diverse and technologically advanced industries, the demand for reliable and efficient wiring harnesses continues to grow. Customized wiring harnesses tailored to the specific needs of different applications—whether in automotive, drones, battery systems, or LED lighting—are essential for ensuring optimal performance, safety, and durability.

Each industry presents unique challenges, from the high-temperature resistance required in vehicles to the lightweight and vibration-resistant designs necessary for drones, or the flexible and corrosion-proof harnesses needed for LED systems. Addressing these demands with precision-engineered wiring harness solutions not only enhances product reliability but also reduces downtime and maintenance costs.

Dongguan Suyi Electronics Co., Ltd. stands out as a professional and experienced manufacturer specializing in custom wiring harnesses for a wide variety of machines and equipment. With advanced design capabilities, stringent quality control, and a commitment to customer satisfaction, Dongguan Suyi Electronics delivers tailored solutions that meet complex technical requirements and industry standards.