Wire harness assemblies are essential components in electrical systems, used to organize and protect electrical wires, ensuring reliable and safe connections. Custom wire harnesses, tailored to specific applications, are critical in industries such as automotive, industrial, aerospace, consumer electronics, and more. Designing a custom wire harness involves careful planning, knowledge of the materials and components, and a deep understanding of the end application's requirements.

In this blog post, we will explore the top 10 tips for designing custom wire harness assemblies. Each tip will guide you through the most important steps of the design process, ensuring your custom wire harness meets all performance, safety, and durability standards.

1. Understand the Project Requirements: The First Step in Design

When designing a custom wire harness, the first step is understanding the application for which it is intended. Different industries have different requirements, so it’s crucial to gather detailed specifications from the client or application engineer.

Key Considerations:

Type of device or equipment: Automotive, industrial, consumer electronics, etc.

Electrical requirements: Voltage, current, power, and signal types.

Environment: Temperature range, exposure to moisture, chemicals, or UV light.

Performance needs: Any special considerations, such as vibration resistance or flexibility.

By understanding these elements, you can design a wire harness that is not only functional but also optimized for its environment.

2. Choose the Right Wire and Insulation Materials

Wire selection is one of the most crucial aspects of designing a custom wire harness. The type of wire and insulation material directly impacts the harness's durability, safety, and performance.

Key Considerations:

Wire material: Copper is the most commonly used conductor, but aluminum and other materials may be used for specialized applications.

Insulation: The insulation material protects the wire and determines its resistance to environmental factors. Common materials include PVC, Teflon, and silicone rubber.

Wire gauge: Choose the appropriate gauge for the wire based on the expected current and voltage.

Table 1: Common Wire Insulation Materials

Insulation Material | Temperature Range | Durability | Common Applications |

PVC | -20°C to 105°C | Moderate | General-purpose wiring |

Teflon | -200°C to 250°C | High | Aerospace, high-temperature applications |

Silicone Rubber | -50°C to 200°C | High | Automotive, flexible wiring |

Selecting the right materials will ensure the wire harness is suitable for its operating environment and meets performance requirements.

3. Plan the Wire Harness Dimensions and Lengths

Once you've selected the appropriate wire and insulation, the next step is to plan the dimensions and lengths of the wire harness. Incorrect lengths or improper dimensioning can lead to installation issues, unnecessary slack, or tension on the wires.

Key Considerations:

Wire length: Accurately measure the required length of each wire to avoid excess or short wiring.

Bundling and routing: Plan the routing of wires to avoid interference, damage, or wear over time.

Slack allowance: Ensure that enough slack is provided to account for movement or future adjustments.

Table 2: Common Wire Length Calculation for Automotive Applications

Component | Wire Length (in meters) |

Engine wiring harness | 3.5 meters |

Interior lighting | 2.2 meters |

Audio system | 1.8 meters |

By planning wire lengths in advance, you can avoid costly mistakes and ensure the wire harness fits perfectly into the designated spaces.

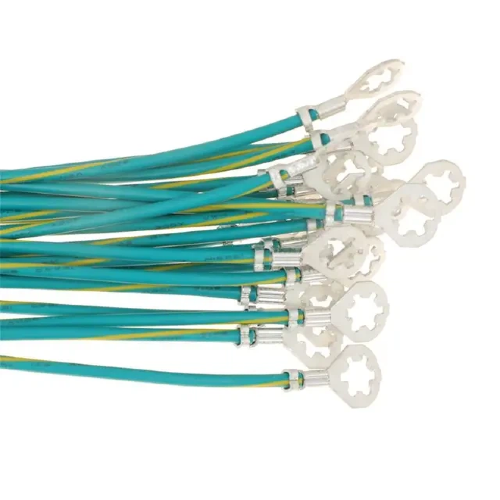

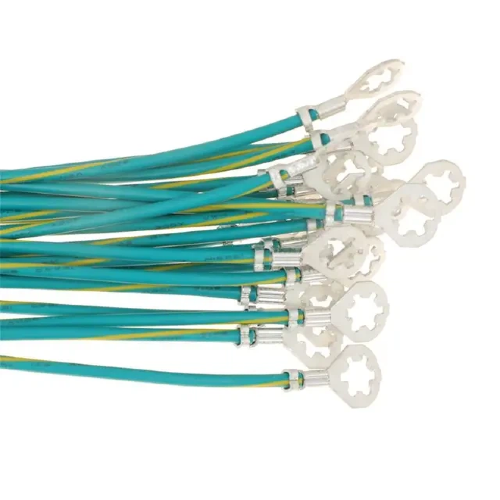

4. Select the Right Terminals and Connectors

Terminals and connectors are crucial components in wire harness assemblies, ensuring secure and reliable electrical connections. The selection of appropriate connectors and terminals is vital to the overall functionality of the harness.

Key Considerations:

Type of connectors: Choose from options such as sealing connectors, quick-connect terminals, or locking connectors based on the application.

Connector size: Ensure connectors match the wire size and expected current.

Corrosion resistance: In harsh environments, choose connectors made from materials that can resist corrosion, such as stainless steel or gold-plated connectors.

Table 3: Common Types of Wire Connectors

Connector Type | Usage | Key Features |

Sealing Connectors | Automotive, industrial | Waterproof, weather-resistant |

Quick-Connect Terminals | Consumer electronics | Easy to install and replace |

Locking Connectors | Aerospace, military | High-vibration resistance |

Choosing the right terminals and connectors will ensure long-lasting, secure electrical connections.

5. Focus on Electrical Performance and Safety

Electrical performance and safety are paramount when designing a custom wire harness. A poorly designed wire harness can lead to short circuits, overheating, or fire hazards.

Key Considerations:

Voltage and current ratings: Ensure that the wires and connectors are rated for the required voltage and current.

Overload protection: Use fuses, circuit breakers, or thermal cutoffs to protect against electrical overload.

Insulation and grounding: Proper grounding and insulation help prevent electrical shock and reduce noise or interference.

6. Optimize the Routing and Layout of the Wire Harness

A well-organized wire harness layout helps prevent tangling, minimizes signal interference, and makes assembly easier. The routing of wires should be optimized for both functionality and ease of installation.

Key Considerations:

Avoiding interference: Route power wires away from signal wires to minimize electromagnetic interference (EMI).

Wire grouping: Group wires based on their function or location in the system to simplify installation and maintenance.

Accessibility: Ensure that critical connectors or wires are easily accessible for future repairs or upgrades.

Table 4: Best Practices for Wire Harness Routing

Routing Tip | Benefit |

Use cable ties or clips | Prevents tangling and stress |

Keep power and signal wires separate | Reduces EMI and crosstalk |

Avoid sharp bends and kinks | Ensures wire integrity |

Optimizing the routing and layout of the wire harness not only ensures its reliability but also makes the installation process much smoother.

7. Consider Flexibility and Serviceability

Designing a wire harness with flexibility and serviceability in mind can significantly extend its lifespan and make future maintenance easier.

Key Considerations:

Flexible materials: Use flexible insulation and multiconductor cables to allow for movement.

Modular design: Consider a modular design that allows individual wires or sections of the harness to be replaced without redoing the entire assembly.

Maintenance access: Ensure that the wire harness can be easily disassembled for future upgrades or repairs.

8. Adhere to Industry Standards and Certifications

When designing custom wire harness assemblies, it’s essential to comply with industry standards and certifications to ensure safety, reliability, and global compatibility.

Key Considerations:

UL certification: Ensure that the materials used in the wire harness meet UL (Underwriters Laboratories) standards for safety.

ISO standards: Follow ISO 9001 for quality management systems and ISO 14001 for environmental management.

RoHS compliance: Ensure that your wire harness is free of hazardous materials by complying with RoHS (Restriction of Hazardous Substances) regulations.

9. Conduct Rigorous Testing and Quality Control

Before finalizing the design and manufacturing of a custom wire harness, thorough testing is crucial to ensure its performance and durability under various conditions.

Key Considerations:

Electrical testing: Test for continuity, insulation resistance, and voltage drop.

Mechanical testing: Test for tensile strength, flexibility, and durability.

Environmental testing: Test the wire harness under extreme temperatures, humidity, and vibration conditions.

Table 5: Testing Methods for Custom Wire Harness

Testing Type | Description | Purpose |

Electrical Testing | Measure resistance, continuity | Ensure proper electrical function |

Mechanical Testing | Test tensile strength, flexibility | Ensure durability and performance |

Environmental Testing | Expose to temperature extremes | Verify reliability in harsh conditions |

Testing ensures that the wire harness will perform as expected in the field and meets safety standards.

10. Choose the Right Manufacturer and Supplier

Selecting the right manufacturer is essential to ensure the timely delivery of high-quality custom wire harnesses. A reliable supplier should offer expertise, quality control, and flexibility to meet your needs.

Key Considerations:

Experience: Choose a manufacturer with experience in your specific industry.

Quality control processes: Ensure the supplier has strict quality control processes in place.

Lead times and communication: Select a supplier who can deliver on time and communicates effectively.

11. Conclusion

Designing a custom wire harness is a meticulous process that requires careful attention to detail, from selecting the right wire and insulation materials to choosing connectors, ensuring electrical performance, and conducting rigorous testing. Following these 10 tips will help ensure that your custom wire harness meets all necessary safety, performance, and durability requirements.

For businesses looking for expert guidance and high-quality custom wire harnesses, Dongguan Suyi Electronics Co., Ltd. is a trusted manufacturer with extensive experience in designing and producing custom solutions. With a focus on precision, high standards of quality control, and the ability to handle diverse industry needs, Suyi offers tailored wire harnesses that are ideal for automotive, industrial, consumer electronics, and more.

Whether you need a one-off prototype or a large production run, Dongguan Suyi Electronics can provide the expertise and reliability you need. Contact their team today to discuss your specific requirements and receive a custom solution designed to meet your exact needs.

12. FAQ

1. What is a custom wire harness, and why is it important?

A custom wire harness is a collection of electrical wires, connectors, and other components bundled together to transmit electrical power and signals in a safe and organized manner. It is important because it ensures reliable performance, safety, and durability in electrical systems.

2. How do I choose the right wire and insulation materials for my wire harness?

The choice of wire and insulation material depends on factors such as the voltage and current requirements, environmental conditions (temperature, moisture, chemicals), and mechanical stress. Common materials include copper for wires and PVC, Teflon, or silicone rubber for insulation.

3. How do I calculate the length of wires for my custom wire harness?

Accurate measurement of the wire length is crucial to avoid excess slack or tension. Measure the required length based on the layout and routing of the harness, considering the space constraints and movement.

4. What types of connectors should I use in my custom wire harness?

Choose connectors based on the type of environment (e.g., waterproof connectors for outdoor use), the current rating, and ease of installation. Common types include sealing connectors, quick-connect terminals, and locking connectors.

5. How do I ensure the safety and electrical performance of my wire harness?

Ensure that your wire harness meets the required voltage and current ratings, uses proper insulation, and includes protective components such as fuses or circuit breakers. Regular testing and adherence to safety standards (e.g., UL certification) also play a crucial role.