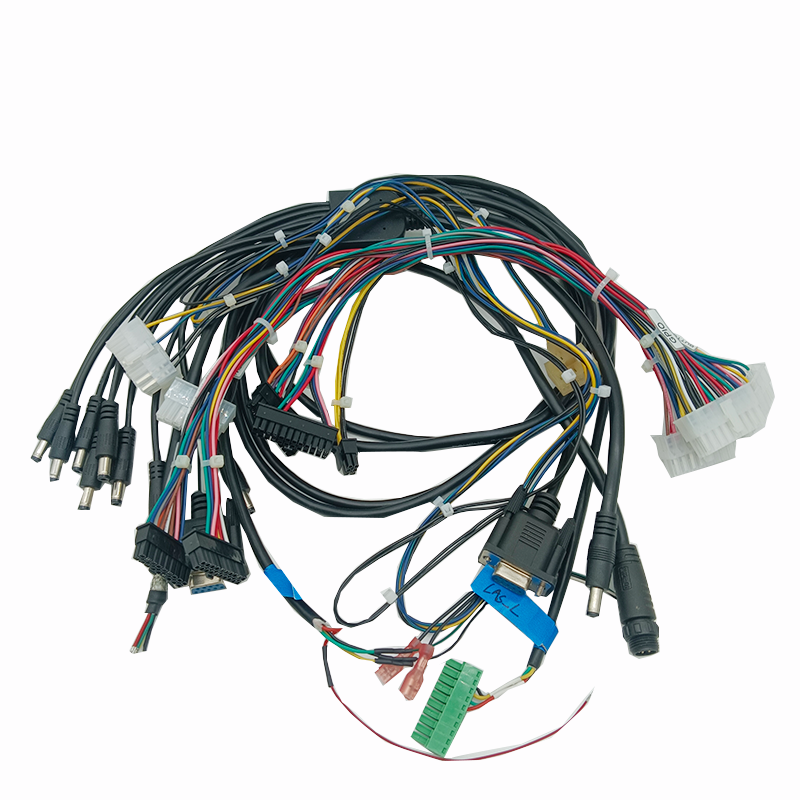

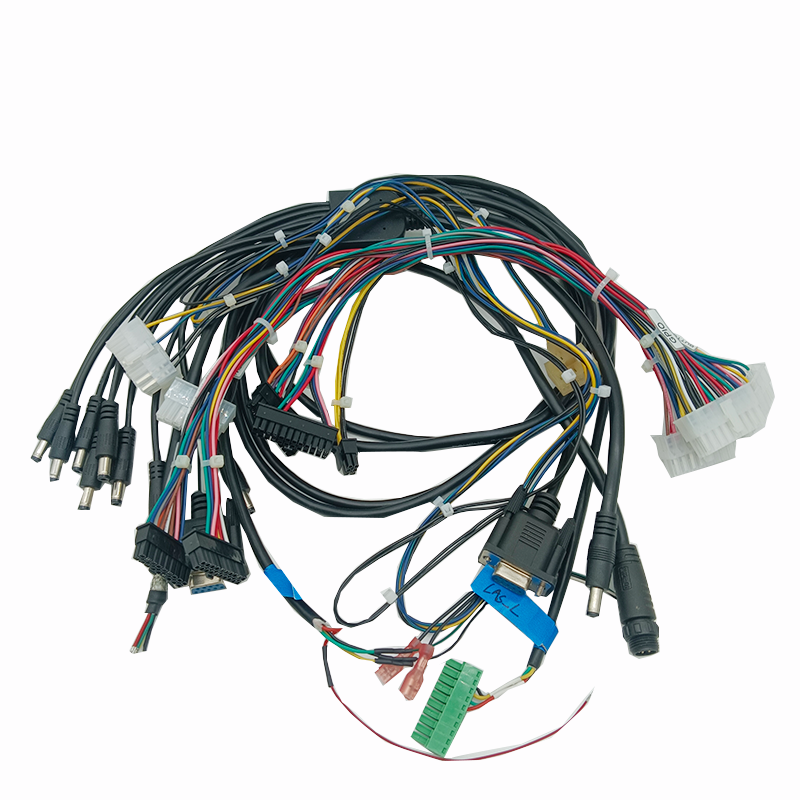

Product Overview

SUYI is a professional manufacturer specializing in customized wire harnesses that cater to diverse industry needs. Our custom wire harnesses are engineered to meet unique customer requirements, ranging from standard electronic connections to specialized applications in harsh environments. By integrating flexible material selection and precision processing, these harnesses not only enhance the performance and reliability of target equipment but also help enterprises reduce production costs and improve operational efficiency. As a core electronic connection component, SUYI’s custom wire harnesses boast broad application prospects across industrial, consumer electronics, medical, and automotive sectors.

Key Features

Flexible Customization for Diverse Scenarios

We offer fully tailored solutions based on equipment type, environmental conditions, and functional demands. From conductor gauge to insulation materials (e.g., PVC, PE, TPU), every parameter is adjustable to ensure compatibility with specific user setups.

Enhanced Equipment Reliability

Our custom wire harnesses undergo strict quality control during production, minimizing signal interference and connection failures. High-quality materials and standardized processing ensure stable performance even in long-term operation.

Cost & Efficiency Optimization

By aligning harness design with actual usage needs, we eliminate redundant components and streamline assembly processes. Helping customers cut material waste and shorten production cycles.

Specifications & Technical Details

Parameter | Details |

Harness Type | Customizable (e.g., single-core, multi-core, shielded, unshielded) |

Conductor Gauge | 32AWG – 10AWG (adjustable based on current and signal requirements) |

Insulation Materials | PVC, PE, TPU, XLPE (selected for environmental resistance) |

Operating Voltage Rating | 0-600V AC/DC (customizable for high-voltage industrial applications) |

Operating Temperature | -40°C – 125°C (standard); up to 150°C for high-temperature options |

Certifications | UL, ROHS 2.0, IEC 60228 |

Flammability Rating | UL 94 V-0 |

Product Application Scenarios

Ideal for sensors, PLCs, and control panels in manufacturing lines. Providing stable signal transmission for automated equipment

Used in 3C products (e.g., computers, printers, audio devices) to connect internal components and ensure smooth data flow.

Applied in non-invasive monitoring equipment (e.g., blood pressure monitors, thermometers) with biocompatible materials optional.

Suitable for in-car electronics (e.g., infotainment, lighting) that require vibration and temperature resistance.

FAQ

Can the harnesses be customized for harsh environments (e.g., dust, moisture)?

Yes. We offer shielded designs and waterproof insulation materials (e.g., TPU) to withstand dust, moisture, and chemical exposure.

What is the typical lead time for a custom order?

For small batches (100-500 units), lead time is 7-10 days; for large batches (1000+ units), it is 15-20 days.

Do you provide test reports for custom harnesses?

Yes. We issue detailed test reports (including electrical performance and material compliance) with each order.