Product Overview

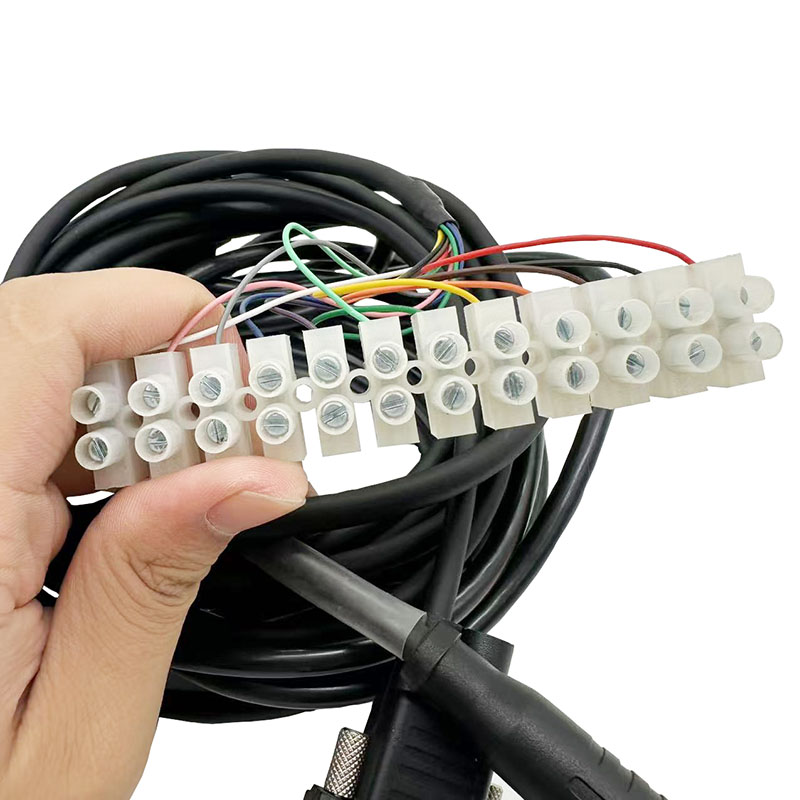

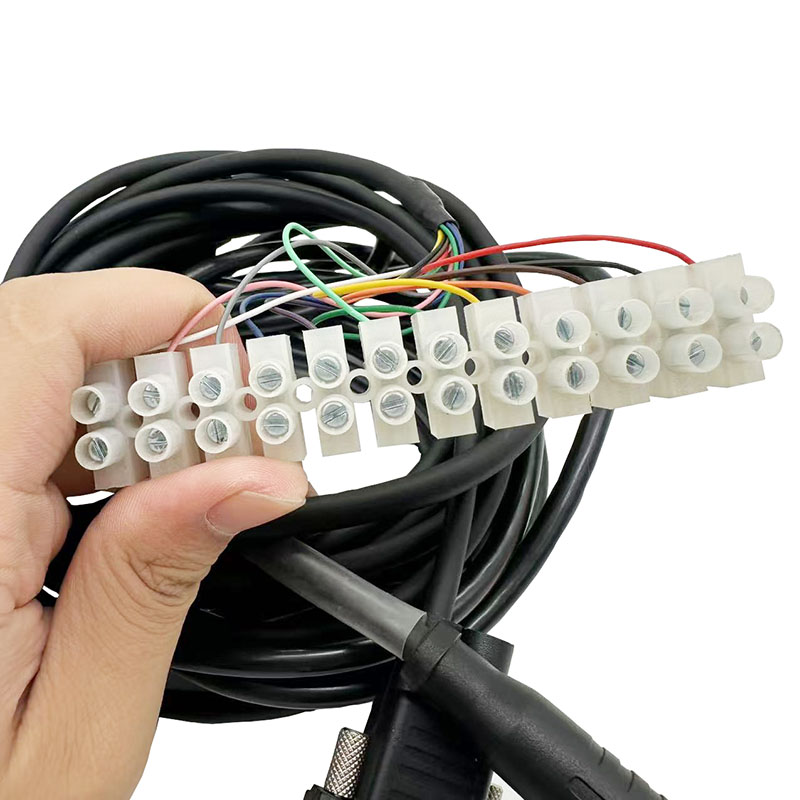

The Custom Automotive Wiring Harness is a versatile, precision-engineered electrical connection solution designed for motorcycles & cars, as well as a wide range of industrial and commercial applications. This harness combines flexible customization options, rugged construction, and compliance with global safety standards to deliver reliable performance across diverse environments. Unlike one-size-fits-all alternatives, it is tailored to your exact specifications—from length and gauge to shielding and connectors—ensuring seamless integration with your equipment. Backed by ISO 9001, UL, RoHS, and REACH certifications, this harness is trusted for automotive, industrial machinery, medical devices, and consumer electronics applications.

Key Features

Tailored Design for Motorcycles & Cars

Customizable length, wire gauge (10AWG-24AWG), and connector types to fit specific vehicle models (passenger cars, motorcycles, commercial vehicles) and electrical systems (engine control, lighting, power transmission).

State-of-the-art automated crimping, soldering, and testing equipment ensure consistent connection quality, minimal signal loss, and long-term durability. Each harness is built to withstand vibration, friction, and temperature fluctuations.

Multi-Industry Compatibility

Beyond automotive and motorcycle use, the harness is engineered for industrial machinery, medical devices, consumer electronics, and aerospace auxiliary equipment—adapting to diverse voltage and performance requirements.

Meets international standards including ISO 9001 (quality), UL (safety), RoHS (environmental), and REACH (chemical compliance), ensuring market access in North America, Europe, Asia, and beyond.

Enhanced Shielding & Protection

Heavy-duty EMI/RFI shielding (braided or foil) prevents electromagnetic interference, while abrasion-resistant sleeves and waterproof coatings (IP65 optional) ensure reliability in harsh operating conditions.

Specifications & Technical Details

Category | Details |

Product Type | Custom Automotive Wiring Harness (motorcycles & cars) |

Compatible Equipment | Automobiles, motorcycles, industrial machinery, medical devices, consumer electronics |

Wire Gauge | 10AWG-24AWG (customizable based on current load) |

Conductor Material | Oxygen-free copper (high conductivity & corrosion resistance) |

Insulation Material | Flame-retardant PVC/PTFE (temperature range: -55℃ to 150℃) |

Shielding Option | Braided EMI/RFI shielding (90% coverage) or foil shielding |

Connector Compatibility | AMP, Deutsch, Yazaki, Sumitomo, and custom connectors |

Manufacturing Process | Automated crimping, laser soldering, 100% continuity testing |

Certifications | ISO 9001, UL 1581, RoHS 2.0, REACH |

Protection Grade | IP65 (standard) / IP67 (optional, for wet environments) |

Lead Time | 7-10 working days (mass production); 5 days (expedited) |

Product Application Scenarios

Automotive & Motorcycle Electrical Systems

Engine Control Units (ECUs): Sensor connections, fuel injection system wiring

Vehicle Lighting: Headlights, turn signals, brake lights, dashboard lighting

Power Transmission: Battery connections, alternator wiring, USB charging ports

Motorcycle-Specific: Ignition systems, instrument panels, LED auxiliary lights

Industrial Machinery

Production Line Equipment: Conveyor belts, robotic arms, control panels

Heavy Machinery: Construction equipment, agricultural machinery, generators

Medical Devices

Diagnostic Equipment: Ultrasound machines, blood pressure monitors

Treatment Instruments: Surgical lighting, portable medical devices (battery wiring)

Consumer Electronics

Smart Home Devices: Smart lighting, home automation control systems

Portable Electronics: Power banks, outdoor gear (waterproof wiring)

Customization Service Process

In-Depth Demand Analysis

Our team collaborates with you to gather detailed requirements: application type (automotive/motorcycle/industrial), voltage/current needs, environmental conditions (temperature, moisture), length, gauge, and connector preferences.

Engineering Solution Design

We develop a 3D wiring diagram and material list, optimizing for performance, durability, and cost-efficiency. We provide design proposals and technical drawings for your approval.

Prototype Development & Testing

We manufacture a functional prototype, conducting rigorous tests (voltage resistance, shielding effectiveness, vibration resistance) to validate performance. Adjustments are made based on your feedback.

Certification & Compliance Validation

For industry-specific applications (e.g., medical devices), we conduct additional compliance testing to meet sector-specific standards (e.g., ISO 13485 for medical use).

Mass Production & Quality Inspection

Upon prototype approval, we initiate mass production with real-time quality monitoring. Each batch undergoes random sampling tests to ensure consistency.

Delivery & After-Sales Training

We deliver the harnesses with detailed technical documentation. For bulk orders, we provide on-site training for installation and maintenance teams.

Quality Assurance & After-Sales Support

Quality Assurance System

ISO 9001-certified production facility with strict process control (IQC, IPQC, FQC).

Comprehensive testing: High-temperature aging test, vibration test, salt spray test, and short-circuit protection test.

Traceability: Each harness is labeled with a batch number for full production traceability.

After-Sales Support

2-year warranty: Coverage for manufacturing defects, including free replacement and repair.

Technical consultation: Expert engineers available to resolve integration or performance issues via video call, email, or phone.

Spare parts supply: Fast delivery of replacement connectors, sleeves, or custom components.

FAQ

Can this harness be customized for my vintage motorcycle model?

Yes. We specialize in custom solutions for both modern and vintage motorcycles/cars. Provide your vehicle’s year, make, model, and electrical system details, and we’ll design a harness that fits perfectly.

Does the harness meet European (CE) and North American (UL) safety standards?

Absolutely. The harness is certified to UL 1581 (North America) and RoHS 2.0/REACH (Europe), ensuring compliance with regional safety and environmental regulations.

What is the maximum temperature the harness can withstand?

The standard version uses PTFE insulation, which tolerates temperatures up to 150℃. For extreme environments (e.g., industrial furnaces), we offer high-temperature-resistant materials (up to 200℃) upon request.

How do I request a custom connector that’s not listed in your specifications?

Simply provide the connector’s part number, technical drawings, or sample, and our engineering team will source or design a compatible solution. We support custom connector molding for bulk orders.