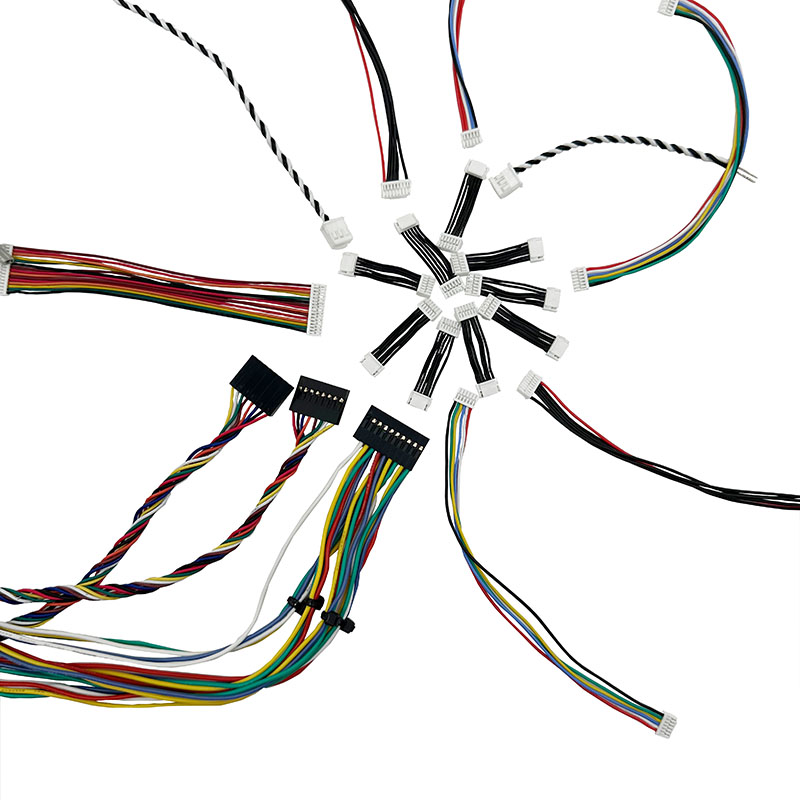

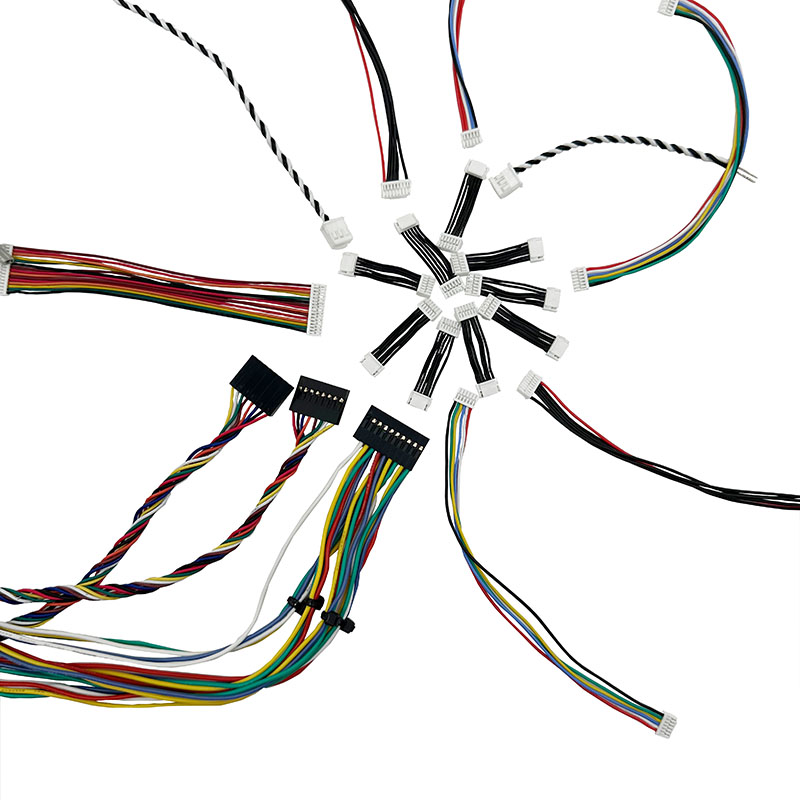

Product Overview

As a professional source factory, SUYI specializes in manufacturing custom wire harness assemblies integrated with JST connectors (XH, ZH, PH series) and MOLEX connectors, covering 2-12 pin configurations. Our wiring harnesses are engineered to meet the diverse needs of various electrical equipment, combining premium materials, precision manufacturing, and strict compliance with international standards. Whether for automotive systems, industrial machinery, or consumer electronics, our JST connector wiring harness delivers exceptional durability, signal integrity, and compatibility, making it a reliable choice for businesses seeking tailored electrical connectivity solutions. All products are ISO 9001, UL, RoHS, and REACH certified, ensuring adherence to global quality and environmental standards.

Key Features

Premium-Grade Material Selection

Our high-quality wiring harness is constructed with top-tier wires, rugged JST/MOLEX connectors, and advanced insulation materials. The wires feature excellent conductivity and resistance to wear, while the connectors ensure secure mating and long-term stability. The insulation layer effectively prevents short circuits and corrosion, extending the product’s service life even in demanding conditions.

Fully Customizable Designs

We offer flexible 2-12 pin wiring harness customization to match your specific application requirements:

Length: Tailored from short-distance connections to long-range wiring solutions.

Wire Gauge: Optimized for current load and signal transmission needs.

Shielding: Optional EMI/RFI shielded wiring harness to block electromagnetic interference.

Connector Types: Compatible with JST XH, ZH, PH, MOLEX, and other popular connector series.

Robust Protection for Harsh Environments

EMI/RFI Shielding: Minimizes signal interference, ensuring stable data and power transmission.

Heat-Resistant Sleeves: Withstands high-temperature operating conditions in industrial and automotive settings.

Waterproof Coatings: Available for automotive wiring harness and outdoor electrical equipment, preventing water ingress and rust.

Precision Manufacturing & Consistent Quality

All custom wire harness products undergo automated crimping, soldering, and testing processes. Automated production eliminates human errors, guaranteeing uniform crimp strength and solder joints. Each harness is 100% inspected for continuity, insulation resistance, and mechanical durability before delivery.

Wide Compatibility Across Industries

Our wiring harnesses are designed to integrate seamlessly with diverse electrical equipment, supporting cross-industry applications. Compliance with international standards ensures compatibility with global electrical systems and components.

Global Compliance & Certifications

All products meet ISO 9001 quality management system standards, UL safety requirements, RoHS environmental regulations, and REACH substance restrictions. Our ISO 9001 certified wiring harness and RoHS compliant wiring harness help customers avoid regulatory risks in global markets.

Specifications & Technical Details

Specification Item | Details |

Connector Type | JST XH, JST ZH, JST PH, MOLEX, and other customized types |

Pin Count | 2-12 pins (customizable per requirements) |

Wire Gauge | 20-30 AWG (optimized for current and signal needs) |

Insulation Material | PVC, TPE, or high-temperature resistant materials |

Shielding Type | EMI/RFI shielding (aluminum foil, braided shield) - optional |

Operating Temperature | -40°C to 125°C (varies by material selection) |

Certifications | ISO 9001, UL, RoHS, REACH |

Customization Range | Length, gauge, shielding, connector type, color coding |

Durability | ≥500 mating cycles (connector) |

Product Application Scenarios

Automotive Industry

Our automotive wiring harness is ideal for in-vehicle electronics, including infotainment systems, sensor connections, and lighting modules. The heat-resistant and anti-interference design adapts to the high-vibration, high-temperature automotive environment.

Industrial Machinery

Suitable for control systems, motors, and sensors in industrial wiring harness applications. The rugged construction withstands dust, moisture, and mechanical stress in factories and production lines.

Consumer Electronics

Used in household appliances, audio-visual equipment, and smart devices. The compact 2-12 pin wiring harness saves space while ensuring reliable signal transmission.

Medical Devices

Our medical device wiring harness meets strict safety and hygiene standards, suitable for diagnostic equipment, monitoring devices, and medical instruments. The biocompatible materials and precise manufacturing ensure patient safety.

Customization Service Process

Consultation & Requirement Collection

Our technical team communicates with customers to clarify key requirements: application scenario, connector type, pin count, wire length, gauge, shielding needs, and certification requirements.

Design & Engineering

Based on collected requirements, we develop 2D/3D designs for the custom wire harness, including circuit diagrams and assembly drawings, and confirm with customers for approval.

Prototype Development

We produce small-batch prototypes to test fit, function, and performance. Customers can verify the prototype and provide feedback for adjustments.

Testing & Validation

Prototypes undergo strict testing: continuity test, insulation resistance test, shielding effectiveness test, and environmental adaptability test (temperature, vibration, moisture).

Mass Production

After prototype approval, we start mass production using automated equipment, ensuring consistent quality and on-time delivery.

Delivery & Installation Guidance

We deliver finished products with detailed documentation (test reports, certification documents) and provide technical support for installation if needed.

Quality Assurance & After-Sales Support

Strict Production Inspection

Incoming Material Inspection: All wires, connectors, and insulation materials are inspected for compliance with standards.

In-Process Inspection: Real-time monitoring of crimping, soldering, and assembly processes.

Final Inspection: 100% testing of each custom wire harness for electrical performance and mechanical quality.

Certification Compliance Guarantee

We maintain valid certifications (ISO 9001, UL, RoHS, REACH) and provide certification documents to customers, ensuring product compliance in target markets.

After-Sales Consultation & Support

Our professional after-sales team provides 24/7 technical consultation, answering questions about installation, usage, and maintenance.

Defect Replacement Policy

If products have quality defects due to manufacturing issues, we offer free replacement within the warranty period (12 months from delivery date).

With a focus on customization, quality, and compliance, SUYI’s custom wire harness solutions provide reliable electrical connectivity for businesses worldwide. Whether you need a 2-pin JST XH harness or a 12-pin MOLEX integrated assembly, we deliver tailored products that meet your exact requirements. Contact us today to start your customization journey!