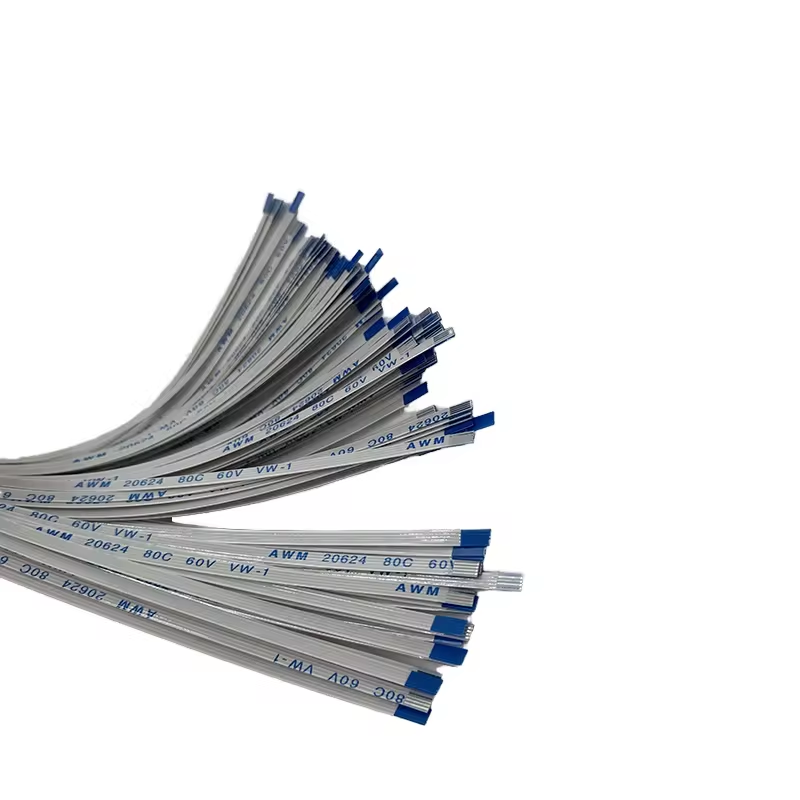

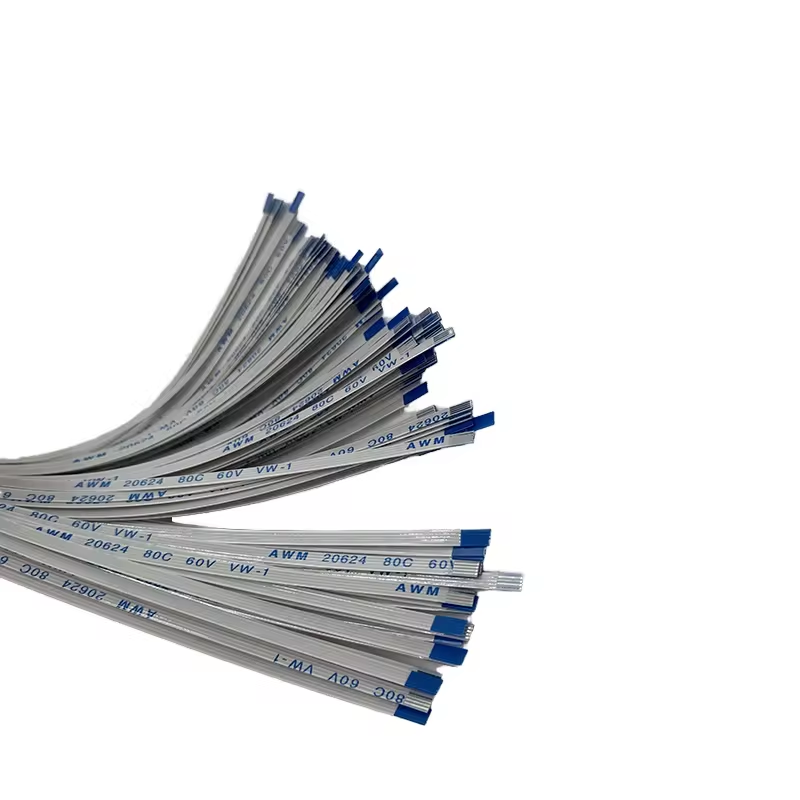

Product Overview

The 6-60pin AWM 20624 FFC Cable (Flexible Flat Cable) from SUYI Electronics is a miniaturized ribbon cable engineered for efficient data transmission in compact electronic systems. It features multiple conductive metal conductors bonded to a flat, flexible plastic insulation film, replacing bulky round cables to streamline cable management. This high-flexibility FFC Cable excels in dynamic applications requiring repeated bending, while its unique structure provides superior EMI/RFI suppression to eliminate wire coupling issues. With a pin count range of 6 to 60, it meets diverse connectivity needs for miniaturized electronic devices, making it a cost-effective solution for connections between moving parts and motherboards, or across PCB boards.

Key Features

AWM 20624 Compliance: Adheres to the AWM 20624 industry standard, ensuring consistent performance and compatibility with global electronic assembly requirements.

6-60pin Versatility: Offers pin counts from 6pin to 60pin (e.g., 10pin, 14pin), supporting custom needs for consumer electronics, industrial equipment, and medical devices.

Exceptional Flexibility: Withstands ≥10,000 bending cycles (180° angle) without conductor damage, ideal for robotic arms or printer head movements.

Space-Saving Design: Flat profile occupies 30-50% less space than round cables, optimizing internal layouts in laptops, cameras, and IoT devices.

Strong EMI/RFI Suppression: Reduces electromagnetic and radio frequency interference, ensuring stable signal transmission for sensitive components like sensors.

Cost-Effective Manufacturing: Standardized parallel conductor structure lowers production costs compared to custom FPCs, suitable for mass-production projects.

Durable Insulation: Available in PET (–20℃+85℃) or PI (–40℃+150℃) materials, adapting to standard or high-temperature environments (e.g., automotive cabins).

Easy Installation: Lightweight and flexible design simplifies routing and assembly, cutting labor time for electronic device production.

Specifications & Technical Details

Parameter | Specification |

Model | 6-60pin AWM 20624 FFC Cable |

Brand | SUYI |

AWM Standard | AWM 20624 |

Pin Count Range | 6pin, 10pin, 14pin, ..., 60pin (customizable) |

Conductor Material | Tinned copper (high conductivity, anti-oxidation) |

Insulation Material | PET (standard) / PI (high-temperature resistant) |

Operating Temperature | PET: –20℃ ~ +85℃; PI: –40℃ ~ +150℃ |

Bending Durability | ≥10,000 cycles (180° bending angle) |

EMI/RFI Performance | Meets IEC 61000-6-2 interference suppression standards |

Lead Time | 3–7 days (samples); 10–15 days (mass production) |

Packaging | Anti-static reels (100pcs/reel) |

Product Application Scenarios

Consumer Electronics

Laptop screen modules: Connects display panels to motherboards, withstanding frequent lid opening/closing.

Printers/scanners: Wires print heads for repeated movement, ensuring stable data transmission during operation.

Digital cameras/camcorders: Saves space in compact housings for internal component connections (e.g., LCD screens, image sensors).

Automotive Electronics

In-vehicle instrument clusters: Transmits signal data for speedometers and fuel gauges, adapting to vehicle vibration.

Central control systems: Links infotainment screens to main controllers, supporting temperature fluctuations in cabins.

Medical Devices

Portable diagnostic tools (e.g., blood glucose meters): Enables compact internal wiring for space-constrained designs.

Endoscope imaging modules: Withstands small-radius bending for precise signal transmission in medical procedures.

Industrial Automation

Robotic arms: Connects joint sensors to control modules, supporting high-frequency bending in production lines.

PLC (Programmable Logic Controller) units: Facilitates board-to-board connections in industrial control cabinets.

Customization Service Process

Requirement Communication

Our team confirms core needs: pin count, insulation material (PET/PI), length, operating temperature, and target device compatibility.

Solution Design

Engineers develop customized FFC Cable layouts, including conductor spacing, insulation thickness, and connector compatibility checks.

Prototype Testing

Small-batch samples undergo performance tests (bending resistance, EMI suppression, conductivity) and are sent to customers for validation.

Mass Production

After sample approval, automated equipment ensures consistent quality, with real-time monitoring of conductor and insulation integrity.

Delivery & Support

Global shipping is arranged, and technical guides are provided for installation and integration.

Quality Assurance & After-Sales Support

Quality Control Measures

Raw material inspection: Tests conductive metal and insulation films for AWM 20624 compliance.

Production testing: Conducts bending, voltage resistance, and EMI tests during manufacturing.

Final inspection: 100% check of pin connectivity, insulation integrity, and dimensional accuracy.

After-Sales Service

Warranty: 12-month coverage for material/workmanship defects.

Technical support: 24/7 online help for installation, performance optimization, and troubleshooting.

Replacement: Free replacements for qualified quality issues within the warranty period.

FAQ

Can I customize a pin count outside the 6-60pin range?

Yes, we support custom pin counts (e.g., 8pin, 70pin) based on device requirements. Contact our sales team for a tailored quote.

PET vs. PI insulation: Which should I choose?

PET is cost-effective for standard environments (–20℃+85℃, e.g., home appliances). PI is recommended for high-temperature scenarios (–40℃+150℃, e.g., automotive engine compartments).

How does this FFC Cable differ from FPC (Flexible Printed Circuit)?

FFC Cable uses a standardized parallel conductor structure (lower cost, simple design) for basic data transmission. FPC uses etched circuits for complex layouts/high-frequency signals (higher cost). Choose FFC Cable for simple, high-flexibility needs.

Is this cable suitable for outdoor use?

It is designed for indoor use. For outdoor applications, we offer waterproof coating customization to enhance environmental resistance.

What is the maximum data transmission rate?

It supports up to 100Mbps, ideal for LCD screens, sensors, and control modules. For high-speed needs (e.g., USB 3.0), contact us for specialized solutions.